The quest for energy resources has driven the oil and gas industry to explore some of the most remote and challenging environments on Earth. As easily accessible reserves dwindle, companies are venturing into deeper waters to tap into untouched reservoirs below the ocean floor. This shift towards deepwater exploration has been made possible by significant advancements in subsea technology. In this article, we explore the cutting-edge technologies enabling oil exploration and production at greater ocean depths, overcoming the formidable challenges of the deep sea.

The Challenges of Deepwater Exploration

Deepwater exploration is a complex endeavor fraught with technical and environmental challenges. The ocean’s depths present extreme conditions that can hinder operations:

- High Pressure and Low Temperatures: At depths exceeding 2,000 meters, equipment must withstand pressures over 200 times the atmospheric pressure at sea level and temperatures approaching freezing.

- Harsh Environmental Conditions: The deep sea is characterized by corrosive saltwater, unpredictable currents, and limited visibility, complicating installation and maintenance of equipment.

- Logistical Hurdles: Remote locations far from shore require substantial logistical support, increasing costs and operational complexity.

- Safety and Environmental Risks: The potential for accidents or spills is amplified in deepwater settings, necessitating robust safety measures and rapid response capabilities.

Overcoming these challenges requires innovative subsea technologies that can operate reliably and efficiently under extreme conditions.

Advances in Subsea Robotics and Remotely Operated Vehicles (ROVs)

One of the most significant advancements in subsea technology is the development of sophisticated Remotely Operated Vehicles (ROVs). These unmanned, tethered robots are the workhorses of deepwater exploration.

Enhanced Capabilities of Modern ROVs

Modern ROVs are equipped with high-definition cameras, manipulator arms, and a suite of sensors, allowing operators to perform intricate tasks from the surface:

- Deepwater Operations: ROVs can operate at depths exceeding 3,000 meters, expanding the reach of exploration activities.

- Precision and Dexterity: Advanced control systems enable precise manipulation of tools and equipment, essential for complex construction and repair tasks.

- Improved Navigation: Enhanced thruster designs and sonar systems improve maneuverability and positioning in challenging underwater environments.

Innovations Driving ROV Efficiency

Recent innovations have focused on increasing the efficiency and reducing the operational costs of ROVs:

- Hybrid ROV/AUV Systems: Combining features of ROVs and Autonomous Underwater Vehicles (AUVs) allows for more versatile operations, switching between manual and autonomous modes as needed.

- Advanced Control Systems: Incorporation of artificial intelligence and machine learning algorithms enables semi-autonomous decision-making, reducing operator workload.

Enhanced Subsea Communication Systems

Effective communication is vital for coordinating subsea operations. Advances in communication technologies have significantly improved data transmission between underwater equipment and surface control centers.

Fiber Optic Communication

Fiber optic cables provide high-bandwidth, low-latency communication links:

- High-Speed Data Transfer: Essential for real-time video feeds, sensor data, and control signals.

- Reliability: Less susceptible to interference compared to traditional copper cables.

Acoustic Communication

In situations where physical cables are impractical, acoustic communication systems offer an alternative:

- Wireless Communication: Uses sound waves to transmit data through water.

- Extended Range: Modern systems can communicate over several kilometers, albeit at lower data rates.

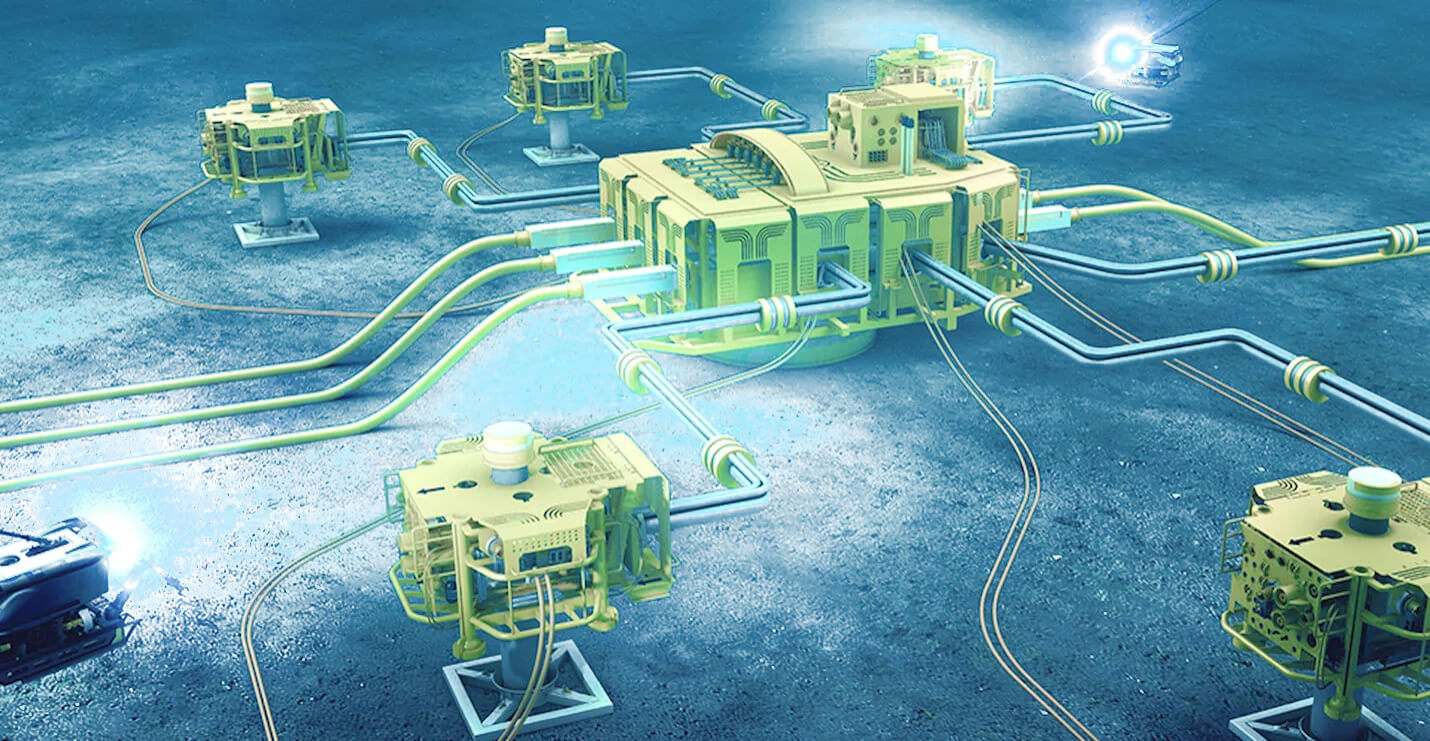

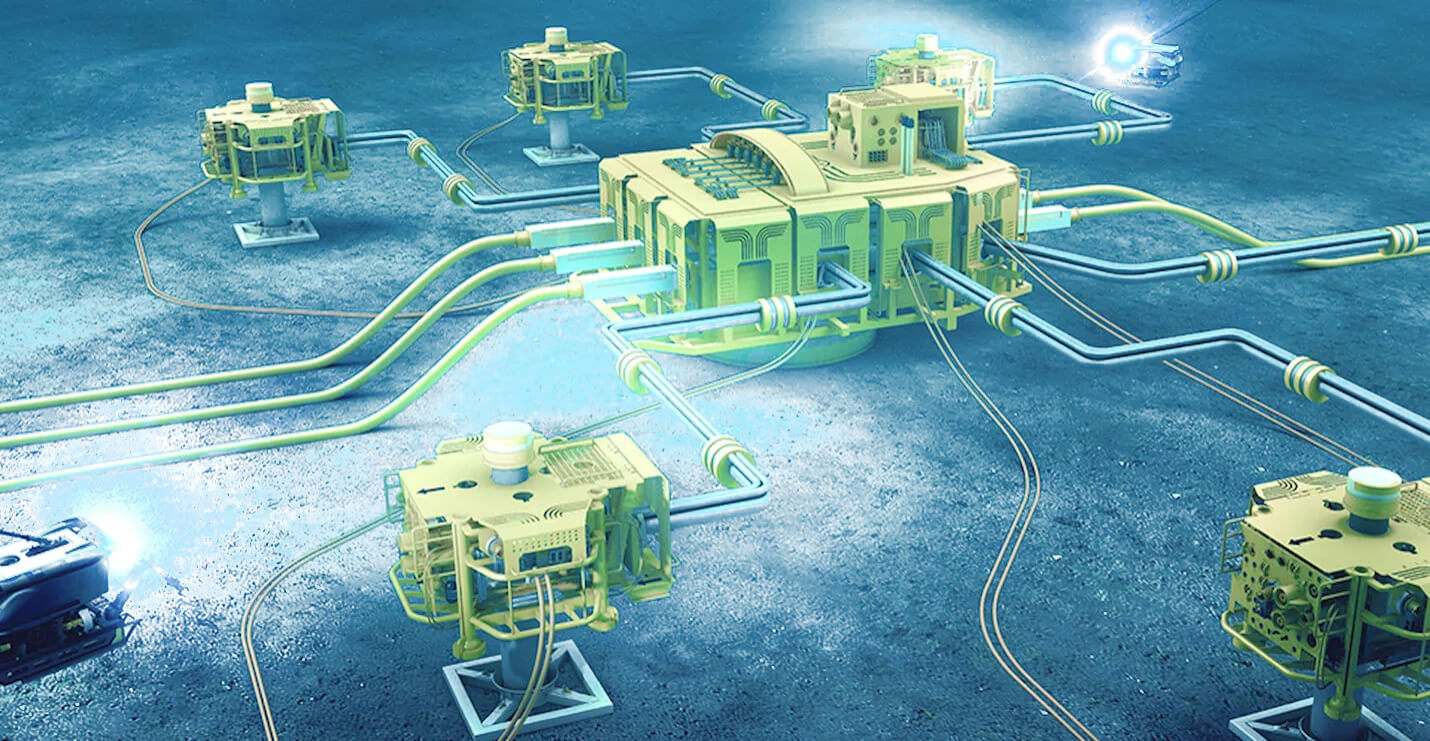

Subsea Processing and Boosting Systems

Traditionally, extracted hydrocarbons are processed on surface facilities. However, subsea processing technologies are shifting these operations to the ocean floor.

Subsea Separation and Boosting

- Separation Systems: Allow for the removal of water and sand from oil and gas mixtures subsea, reducing the amount of material lifted to the surface.

- Multiphase Boosting Pumps: Increase the pressure of the hydrocarbon flow, enabling transportation over long distances without the need for surface compressors.

Benefits of Subsea Processing

- Cost Reduction: Eliminates the need for large surface platforms, reducing capital and operational expenditures.

- Enhanced Recovery: Improves flow rates and recovery from reservoirs with low pressure.

- Environmental Impact: Minimizes the surface footprint and potential for spills.

Improved Materials and Design

Engineering materials capable of withstanding deep-sea conditions are crucial for reliable operations.

Advanced Metallurgy and Composites

- Corrosion-Resistant Alloys: Materials like titanium and duplex stainless steels offer superior resistance to corrosion and fatigue.

- Composite Materials: High-strength, lightweight composites reduce weight and are used in risers and umbilicals.

Innovative Structural Designs

- Flexible Risers: Allow for movement and absorb stresses caused by currents and waves.

- Modular Equipment: Simplifies installation and maintenance, enabling quicker deployment.

Autonomous Underwater Vehicles (AUVs)

AUVs are unmanned, untethered submarines that operate autonomously, performing pre-programmed missions.

Applications in Exploration

- Seabed Mapping: High-resolution sonar and imaging systems create detailed maps of the ocean floor.

- Pipeline Inspection: Autonomous inspections of pipelines and infrastructure for maintenance planning.

- Environmental Monitoring: Collect data on oceanographic conditions and marine life.

Technological Advancements

- Extended Mission Duration: Improvements in battery technology allow for longer missions.

- Enhanced Sensors: Incorporation of advanced sensors improves data quality and scope.

Digital Technologies and Data Analytics

The integration of digital technologies is transforming subsea operations through enhanced monitoring and optimization.

Internet of Things (IoT) and Sensors

- Real-Time Monitoring: Networks of sensors collect data on equipment performance and environmental conditions.

- Predictive Maintenance: Data analytics predict equipment failures before they occur, reducing downtime.

Artificial Intelligence (AI) and Machine Learning

- Data Analysis: AI algorithms analyze vast amounts of data to optimize production and identify trends.

- Autonomous Decision-Making: Machine learning enables systems to adapt and respond to changing conditions autonomously.

Case Studies of Technological Implementation

The Gulf of Mexico Deepwater Projects

Operators have successfully deployed subsea processing systems, including separation and boosting, to enhance production in deepwater fields.

Offshore Brazil Developments

Advanced ROVs and AUVs have been critical in exploring the pre-salt formations located under thick layers of salt beneath the seabed.

Environmental Considerations

As the industry pushes into deeper waters, minimizing environmental impact is more important than ever.

Advanced Monitoring Systems

- Leak Detection: High-sensitivity sensors detect leaks early, allowing for rapid response.

- Impact Assessment: Continuous monitoring of the marine environment to assess and mitigate impacts.

Sustainable Practices

- Reduced Emissions: Subsea processing reduces flaring and venting emissions.

- Smaller Footprint: Elimination of large surface facilities decreases the ecological disturbance.

The Future of Subsea Technology

The future holds exciting possibilities for further advancements:

Robotics and Automation

- Swarm Robotics: Coordinated groups of smaller robots could perform tasks more efficiently.

- Advanced AI: Greater autonomy in operations, reducing human intervention.

New Frontiers

- Ultra-Deepwater Exploration: Pushing beyond current depth limits to access new reserves.

- Integration with Renewable Energy: Hybrid systems combining oil and gas operations with offshore wind or tidal energy.

Conclusion

Advancements in subsea technology have been pivotal in enabling the oil and gas industry to explore and produce resources from the deepest parts of the ocean. Innovations in robotics, communication, processing, materials, and digital technologies have addressed the formidable challenges of deepwater environments. As the industry continues to evolve, these technologies will play a crucial role in meeting global energy demands while striving for sustainability and environmental stewardship.

By embracing these technological advancements, the industry not only enhances its capabilities but also sets the stage for a future where energy production is more efficient, safe, and environmentally conscious. Continued investment in research and development is essential to drive innovation and unlock the full potential of subsea exploration.