The oil and gas industry has long been the backbone of global energy supply, fueling economies and empowering societies worldwide. However, as reserves become harder to find and extract, and as environmental concerns intensify, the industry is under increasing pressure to optimize operations and reduce costs. Enter big data analytics—a transformative force that’s revolutionizing exploration and production (E&P) processes. By harnessing vast amounts of data generated in the field, companies can make smarter decisions, improve efficiency, and gain a competitive edge.

In today’s digital era, every operation in the oil and gas sector generates data. From seismic surveys and drilling rigs to production facilities and distribution networks, sensors and monitoring equipment collect a deluge of information. This data holds the key to unlocking new reserves, optimizing production, and ensuring safety. However, the sheer volume and complexity of this data demand advanced analytics to extract meaningful insights.

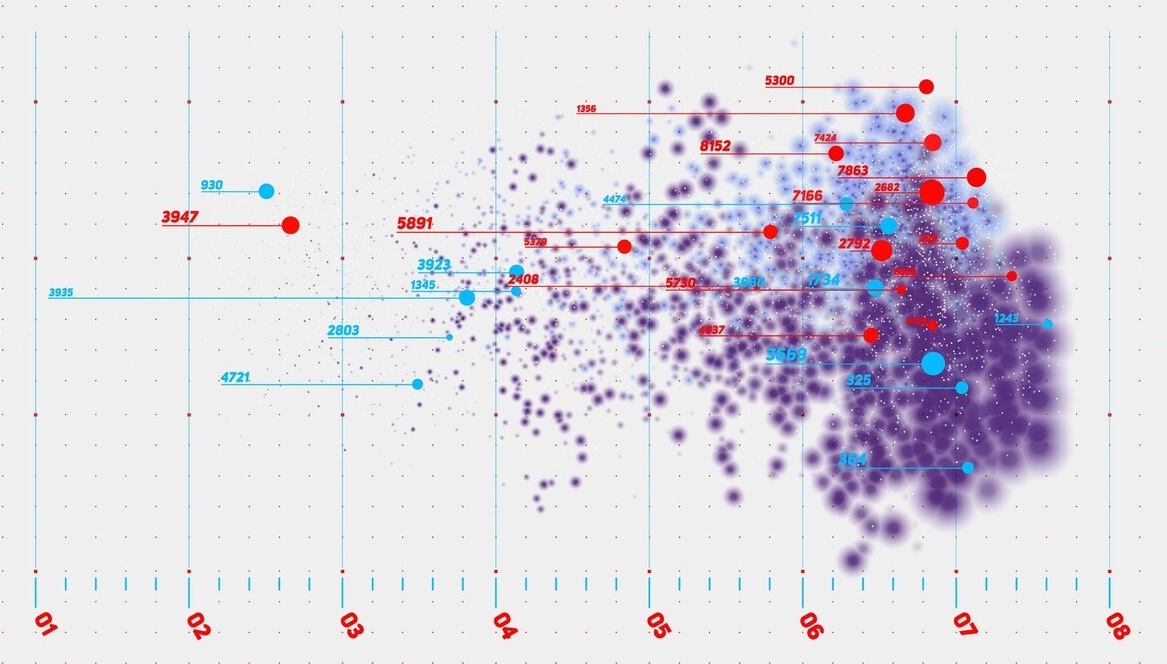

Exploration begins with identifying potential oil and gas reserves, a process that traditionally relies on seismic surveys. These surveys produce massive datasets that represent subsurface geological formations. Big data analytics enables geoscientists to process and interpret these datasets more accurately and quickly.

Advanced Algorithms and Machine Learning: By applying machine learning algorithms, seismic data can be analyzed to detect patterns and anomalies that may indicate the presence of hydrocarbons. This reduces the time required to identify promising sites and increases the success rate of drilling efforts.

3D and 4D Modeling: Data analytics facilitates the creation of detailed 3D models of subsurface formations. Additionally, time-lapse 4D models help monitor how reservoirs change over time, providing insights into fluid movement and reservoir depletion.

Combining geological data with geographical information systems (GIS) allows for comprehensive geospatial analysis. Data analytics tools can overlay various data layers—such as rock properties, fault lines, and previous drilling results—to identify optimal drilling locations.

Advanced sensors on exploration equipment provide real-time data feeds. Big data platforms can process this information instantly, allowing for immediate decision-making. This agility reduces the risks associated with drilling in unknown territories and minimizes downtime.

Equipment failure can lead to costly downtime and safety hazards. Big data analytics empowers companies to implement predictive maintenance strategies.

Sensor Data Utilization: By analyzing sensor data from machinery, algorithms can predict when a component is likely to fail. Maintenance can then be scheduled proactively, reducing unexpected breakdowns.

Cost Reduction: Predictive maintenance not only extends the lifespan of equipment but also reduces repair costs and production interruptions.

Data analytics plays a critical role in enhancing production efficiency.

Reservoir Management: Continuous monitoring of reservoir performance allows engineers to adjust extraction methods to maximize output. Data models can simulate reservoir behavior under different scenarios, guiding optimal production strategies.

Process Efficiency: Analyzing data from the production process identifies bottlenecks and inefficiencies. Adjustments can be made to streamline operations, improve flow rates, and reduce energy consumption.

Automation is increasingly prevalent in the oil and gas industry, and big data analytics is at its core.

Remote Operations: Data analytics supports remote monitoring and control of facilities, which is especially valuable in offshore or hard-to-reach locations.

Safety Enhancements: Automated systems can detect hazardous conditions through data analysis and execute safety protocols without human intervention, reducing the risk of accidents.

Royal Dutch Shell has partnered with technology companies to develop cognitive platforms that analyze geological data. Using machine learning, Shell can interpret seismic images faster and with greater accuracy, accelerating exploration efforts.

BP employs advanced data analytics to optimize drilling operations. By analyzing data from drill bits and sensors, BP can adjust parameters in real-time, reducing drilling times and costs.

Chevron has invested in digital technologies, including big data analytics, to enhance its E&P operations. Data-driven decision-making has improved efficiency across their global operations, from exploration to refining.

Data analytics allows for faster processing of complex datasets, leading to quicker decision-making. This efficiency reduces the time from exploration to production, lowering operational costs.

By optimizing processes and predictive maintenance, companies can significantly cut expenses related to equipment, labor, and energy consumption.

Predictive analytics helps in identifying potential safety risks before incidents occur. Automated systems can respond to hazardous situations promptly, protecting personnel and the environment.

Accurate data analysis leads to better reservoir management, ensuring that extraction methods maximize recovery while minimizing waste.

The vast amount of data generated poses storage and management challenges. Companies need robust infrastructure to store, process, and secure data.

As operations become more digitized, the exposure to cyber threats increases. Protecting sensitive data and critical infrastructure from cyberattacks is paramount.

There is a growing demand for professionals skilled in both petroleum engineering and data science. Bridging this talent gap is essential for fully leveraging big data analytics.

Many companies still operate with legacy equipment and software that may not be compatible with modern data analytics tools. Integrating new technologies requires significant investment and planning.

The integration of AI and machine learning will continue to advance, enabling more sophisticated data analysis. AI can enhance predictive models, improve automation, and uncover insights that were previously inaccessible.

IoT devices will proliferate across exploration and production sites, providing more data points. Edge computing will process data at the source, reducing latency and bandwidth requirements.

Cloud platforms offer scalable resources for data storage and processing. They enable collaboration across different locations and facilitate the deployment of analytics tools.

Creating digital replicas of physical assets (digital twins) allows for simulation and analysis of equipment and processes in a virtual environment. This can optimize performance and predict future outcomes.

The oil and gas industry stands at the crossroads of traditional practices and digital innovation. Big data analytics is not just a tool but a catalyst for transforming how companies approach exploration and production.

By embracing data-driven strategies, companies can:

Big data analytics is revolutionizing the exploration and production processes in the oil and gas industry. By harnessing the power of data, companies can unlock new reserves, optimize production, reduce costs, and enhance safety. While challenges exist, the benefits far outweigh the hurdles.

The future of oil and gas lies in digital transformation. Companies that invest in big data analytics today will be better positioned to navigate the complexities of the industry tomorrow. As technology continues to advance, the possibilities for innovation in exploration and production are boundless.