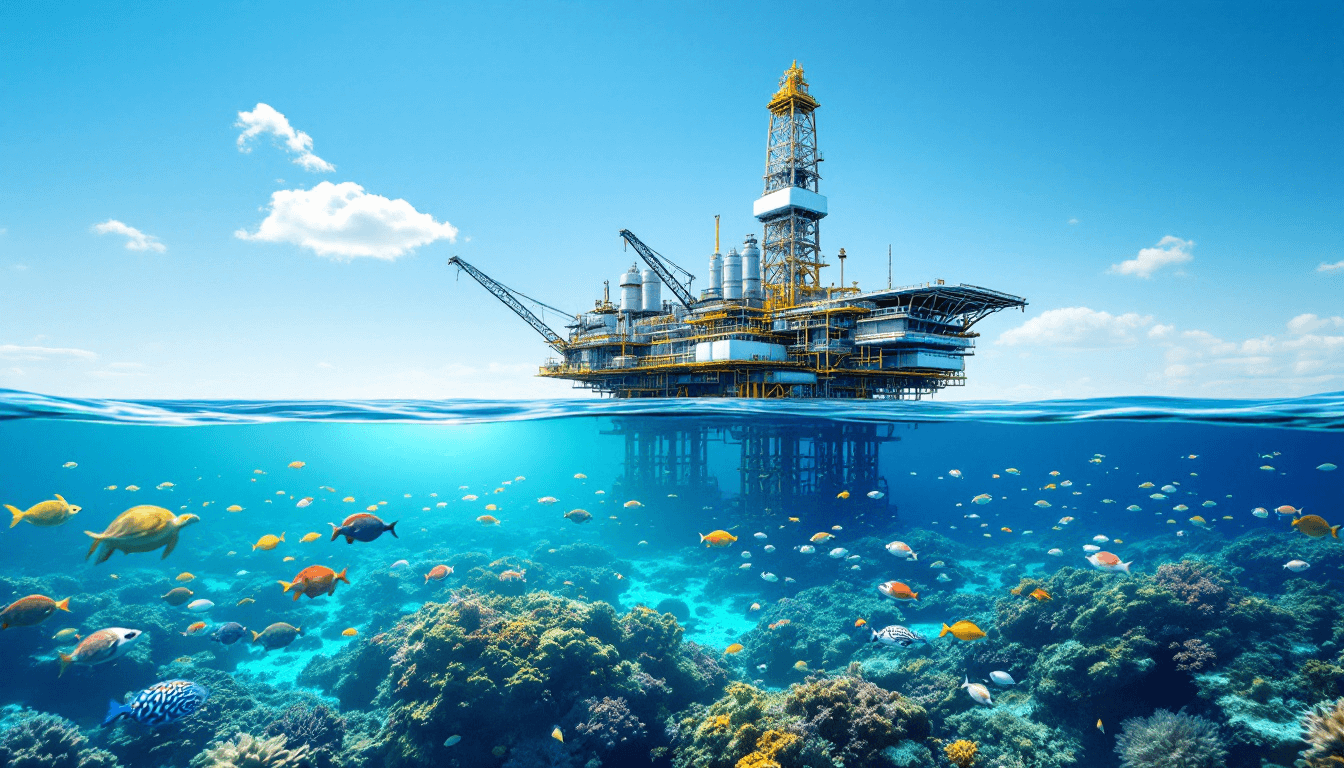

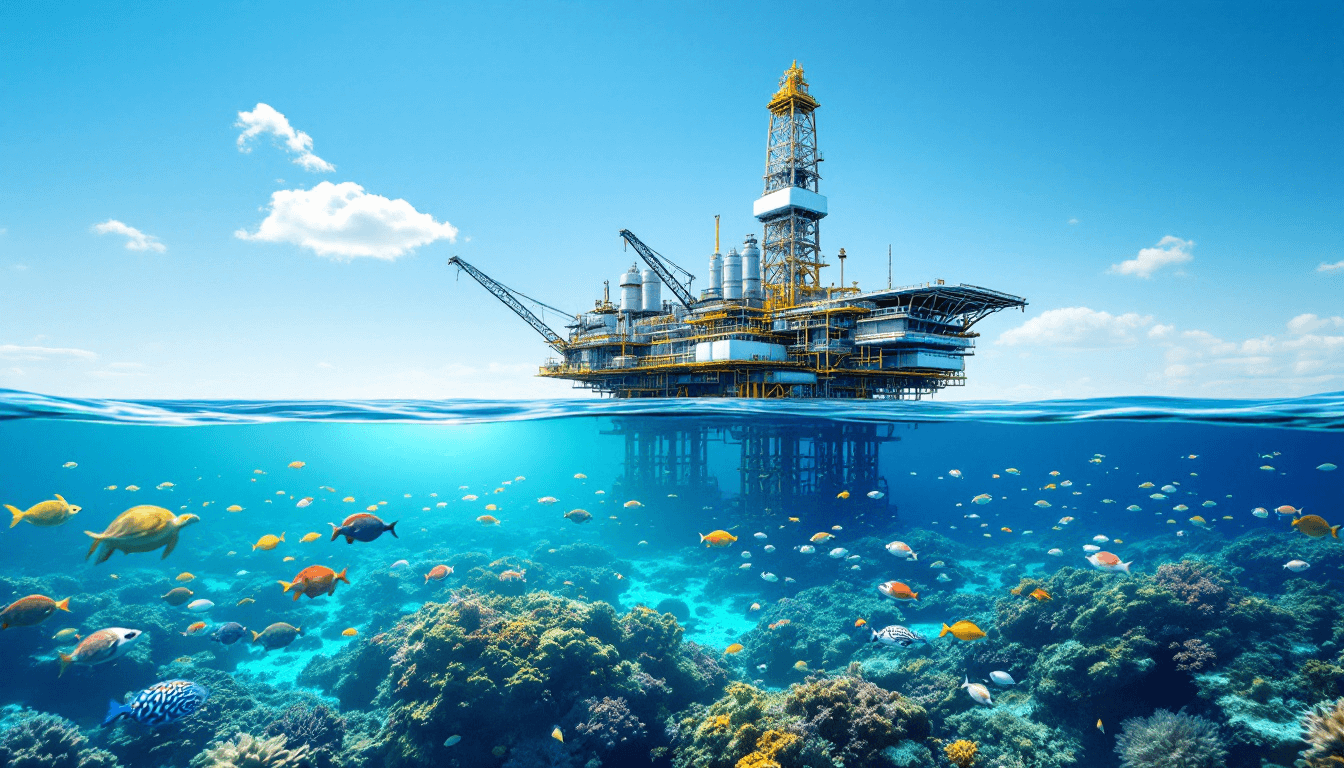

The oil and gas industry has long been a cornerstone of global energy supply, fueling economies and providing essential resources for modern life. However, oil production poses significant environmental challenges, from greenhouse gas emissions to habitat disruption. In an era where environmental stewardship is paramount, companies are increasingly adopting best practices to minimize their ecological footprint and meet stringent environmental standards. This article explores the strategies and technologies employed by oil producers to enhance sustainability and compliance.

The Environmental Challenges in Oil Production

Oil production involves complex processes that can impact the environment in various ways:

- Greenhouse Gas Emissions: Exploration, extraction, and refining activities release significant amounts of carbon dioxide (CO₂) and methane (CH₄), potent greenhouse gases contributing to climate change.

- Oil Spills and Leaks: Accidents during drilling, transportation, or storage can lead to oil spills, causing severe damage to marine and terrestrial ecosystems.

- Water Pollution: Discharge of contaminated water, known as produced water, can pollute waterways if not properly treated.

- Waste Generation: Drilling operations generate solid waste, including drilling muds and cuttings, which may contain hazardous substances.

- Habitat Disruption: Infrastructure development for oil production can lead to deforestation and loss of biodiversity.

Regulatory Framework and Environmental Standards

To mitigate these impacts, governments and international bodies have established regulations and standards:

- International Standards: Organizations like the International Organization for Standardization (ISO) provide guidelines (e.g., ISO 14001 for Environmental Management Systems) that help companies manage their environmental responsibilities systematically.

- National Regulations: Countries enforce laws governing emissions, waste disposal, and spill prevention. For instance, the U.S. Environmental Protection Agency (EPA) regulates air and water pollution under the Clean Air Act and the Clean Water Act.

- Industry Guidelines: The American Petroleum Institute (API) offers standards and recommended practices for safe and environmentally sound operations.

Compliance with these regulations is not only a legal obligation but also essential for maintaining a company’s reputation and social license to operate.

Implementing Best Practices in Oil Production

1. Emission Reduction Strategies

- Cleaner Technologies: Adoption of advanced technologies like low-emission compressors and vapor recovery units reduces the release of volatile organic compounds (VOCs) and methane during production.

- Flaring Reduction: Companies minimize flaring—the burning of excess natural gas—by capturing and utilizing gas that would otherwise be wasted, thereby reducing CO₂ emissions.

- Carbon Capture and Storage (CCS): CCS technologies capture CO₂ emissions from production facilities and store them underground, preventing them from entering the atmosphere.

2. Spill Prevention and Response

- Advanced Monitoring Systems: Use of sensors, drones, and satellite imagery enhances the detection of leaks and spills, allowing for rapid response.

- Regular Maintenance and Inspection: Routine checks of pipelines and equipment help identify potential failures before they lead to environmental incidents.

- Emergency Response Plans: Comprehensive plans ensure quick mobilization of resources to contain and mitigate spills, minimizing environmental damage.

3. Waste Management

- Proper Disposal Practices: Drilling wastes are treated to remove hazardous substances before disposal, or are injected into deep wells designed to prevent contamination of groundwater.

- Recycling and Reuse: Materials like drilling fluids and produced water are recycled for use in other operations, reducing the demand for fresh resources.

4. Water Management

- Produced Water Treatment: Technologies such as membrane filtration and evaporation are employed to treat produced water, allowing for its safe discharge or reuse.

- Water Conservation Techniques: Practices like closed-loop systems minimize water usage and prevent contamination.

5. Biodiversity and Habitat Protection

- Minimizing Operational Footprint: Companies design facilities to occupy less space and utilize directional drilling to access oil reserves with fewer surface impacts.

- Restoration Initiatives: Post-operation restoration of sites includes replanting vegetation and rehabilitating wildlife habitats.

Leveraging Technology and Innovation

Advancements in technology play a crucial role in enhancing environmental performance:

- Digitalization and Automation: Real-time data analytics improve operational efficiency and environmental monitoring.

- Artificial Intelligence (AI): AI algorithms predict equipment failures, reducing the risk of leaks and spills.

- Drones and Robotics: Unmanned systems conduct inspections in hazardous areas, protecting workers and providing detailed environmental assessments.

Case Studies: Leading by Example

Company A: Emission Reduction Success

Company A implemented a comprehensive emission management program, investing in vapor recovery units and methane leak detection technologies. As a result, they achieved a 50% reduction in methane emissions over five years, exceeding regulatory requirements.

Company B: Innovative Water Management

Faced with water scarcity, Company B developed a water recycling system that treats and reuses 80% of the water from their operations. This initiative significantly reduced freshwater withdrawal and set a new standard in water stewardship.

Challenges in Implementing Best Practices

While the benefits are clear, companies face obstacles:

- Economic Factors: High initial costs of new technologies and processes can be a barrier, especially for smaller companies.

- Technical Limitations: Some best practices require specialized expertise and equipment not readily available in all regions.

- Regulatory Hurdles: Navigating complex regulations across different jurisdictions can be challenging, necessitating significant administrative resources.

The Way Forward: Collaboration and Continuous Improvement

To overcome these challenges, the industry must adopt a collaborative approach:

- Stakeholder Engagement: Engaging with governments, communities, and environmental organizations fosters transparency and shared responsibility.

- Investing in Research and Development: Continuous investment in innovation leads to more efficient and cost-effective solutions.

- Adopting International Best Practices: Sharing knowledge and standardizing practices globally enhance overall environmental performance.

- Emphasizing Corporate Responsibility: Integrating environmental objectives into corporate strategies aligns business goals with sustainability.

Conclusion

The oil and gas industry stands at a pivotal point where environmental responsibility is integral to its future. By implementing best practices, adopting innovative technologies, and committing to continuous improvement, companies can significantly reduce their environmental impact. These efforts not only ensure compliance with environmental standards but also contribute to the long-term viability of the industry in a world increasingly focused on sustainability.

By prioritizing environmental stewardship, the oil industry can continue to meet the world’s energy needs while protecting the planet for future generations.