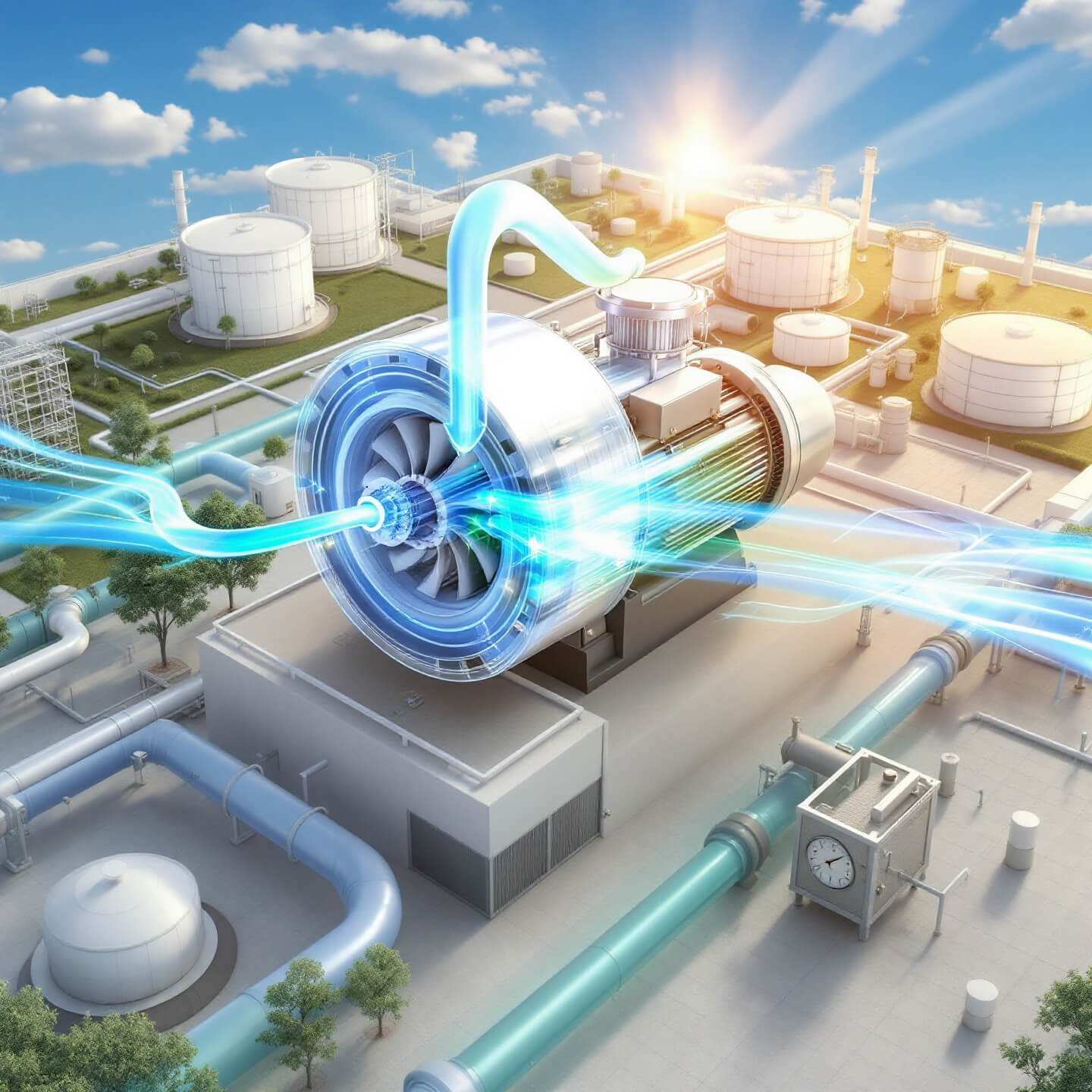

Natural gas has become an indispensable resource in the global energy landscape, offering a cleaner-burning alternative to other fossil fuels like coal and oil. As the demand for natural gas continues to rise, so does the need for efficient and effective processing methods. One of the critical components in natural gas processing is the turbo compressor. Turbo compressors play a pivotal role in enhancing the efficiency, reliability, and overall quality of the processed gas. This article delves into the importance of turbo compressors in natural gas processing, exploring how they work and their impact on efficiency and product quality.

Turbo compressors, also known as centrifugal compressors, are mechanical devices that increase the pressure of a gas by mechanically accelerating it through a rotating impeller. Unlike positive displacement compressors, which trap and compress gas in a confined space, turbo compressors impart kinetic energy to the gas, which is then converted into pressure energy.

There are mainly two types of turbo compressors used in the industry:

Both types are integral in various stages of natural gas processing, depending on the specific requirements of pressure and flow rate.

In the initial stages of natural gas production, turbo compressors are essential for gathering gas from multiple wells and transporting it to processing facilities. They boost the gas pressure to overcome the frictional losses in pipelines, ensuring a continuous and efficient flow to processing plants.

Natural gas extracted from the earth contains impurities like water vapor, hydrogen sulfide, carbon dioxide, and other hydrocarbons. Turbo compressors are utilized in several gas processing operations, including:

By compressing the gas, turbo compressors facilitate these processes by providing the necessary pressure and temperature conditions for optimal separation and purification.

In liquefied natural gas (LNG) production, turbo compressors are critical in cooling the natural gas to extremely low temperatures (-162°C) to convert it into liquid form. Compressors increase the gas pressure before it enters the cryogenic heat exchangers, enhancing the efficiency of the liquefaction process.

After processing, natural gas may be stored in underground facilities or transported via pipelines to end-users. Turbo compressors maintain the required pressures for storage injection and pipeline distribution, ensuring that the gas reaches consumers safely and efficiently.

Turbo compressors are designed for high efficiency, which is vital given the significant energy consumption associated with gas compression. Advanced designs and technologies have led to compressors that operate at optimal efficiency levels, reducing operational costs and energy usage.

Reliability is crucial in natural gas processing to prevent downtime and ensure continuous operation. Turbo compressors are built for robust performance with features like:

Enhanced reliability translates to fewer interruptions, consistent processing rates, and lower maintenance costs.

Efficient compression contributes to the overall optimization of natural gas processing. Precise control over pressure and flow rates allows for:

The efficiency of turbo compressors directly affects the purity of the processed natural gas. Proper compression levels ensure that separation processes effectively remove impurities, resulting in higher quality gas that meets industry and regulatory standards.

Advanced sealing and filtration in turbo compressors prevent oil and other contaminants from entering the gas stream. This is essential for maintaining gas purity and preventing downstream equipment fouling or corrosion.

Efficient compression enhances the recovery of valuable hydrocarbons during NGL extraction. By achieving the necessary pressures for condensation, turbo compressors facilitate the separation of ethane, propane, and other NGLs, contributing to product quality and additional revenue streams.

The use of CFD in compressor design has led to significant improvements in aerodynamic efficiency. By simulating gas flow within the compressor, designers can optimize blade shapes and configurations to reduce losses and enhance performance.

The adoption of magnetic bearings eliminates mechanical contact, reducing friction and wear. This results in:

Modern turbo compressors are integrated with advanced control systems, allowing for:

By operating more efficiently, turbo compressors help reduce greenhouse gas emissions associated with natural gas processing. Lower energy consumption means fewer emissions from power generation.

Technological advancements have led to quieter compressor designs, reducing noise pollution in and around processing facilities.

Efficient natural gas processing complements the intermittent nature of renewable energy sources. Turbo compressors enable faster ramp-up of gas supply to balance the grid when renewable output is low.

Turbo compressors involve significant capital expenditure. However, the long-term benefits of efficiency and reliability often justify the initial costs.

While modern designs reduce maintenance needs, compressors still require regular servicing. Implementing comprehensive maintenance programs is essential to maximize uptime and performance.

Operating under high pressures and temperatures demands materials that can withstand extreme conditions. Ongoing research into new materials and designs is critical to overcoming these limitations.

The role of turbo compressors in natural gas processing is set to grow with the increasing demand for natural gas and the pursuit of greater efficiency and environmental sustainability. Future developments may include:

Turbo compressors are a cornerstone of modern natural gas processing, significantly impacting efficiency and product quality. Their ability to provide precise control over gas pressures and flow rates enables effective purification, separation, and liquefaction processes. Technological advancements continue to enhance their performance, reliability, and environmental compatibility. As the natural gas industry evolves, turbo compressors will remain integral, driving progress toward more efficient, sustainable, and high-quality natural gas production.

By understanding and leveraging the capabilities of turbo compressors, natural gas processors can optimize operations, reduce costs, and meet the growing global energy demands more effectively.