The oil and gas industry remains a cornerstone of the global energy landscape, powering economies and enabling modern lifestyles. As easily accessible oil reserves dwindle, the need to optimize the extraction of remaining resources becomes increasingly critical. Enhanced Oil Recovery (EOR) techniques have emerged as vital methods to maximize output from existing fields. Central to the success and progression of these techniques are the innovations in mechanical engineering. Mechanical engineering advancements are driving more effective and efficient oil recovery methods, pushing the boundaries of what is possible in hydrocarbon extraction.

Understanding Enhanced Oil Recovery

Enhanced Oil Recovery refers to a set of techniques implemented to increase the amount of crude oil that can be extracted from an oil field. Traditional methods often leave a significant portion of the oil in the reservoir—sometimes as much as 60-70%. EOR aims to recover these remaining reserves, extending the life of oil fields and maximizing resource utilization. The primary categories of EOR include thermal recovery, gas injection, chemical flooding, and microbial methods, each with specific mechanical engineering challenges and solutions.

The Role of Mechanical Engineering in Oil Recovery

Mechanical engineering plays a pivotal role in the design, implementation, and optimization of equipment and processes used in oil extraction. From drilling rigs and pumping systems to the materials used in construction, mechanical engineering innovations are crucial for enhancing efficiency, safety, and environmental compliance. In EOR, the mechanical aspect is intertwined with chemical and fluid dynamics processes, requiring sophisticated engineering solutions to handle complex operations under challenging conditions.

Innovations in Drilling Technologies

Advancements in drilling technologies have been instrumental in accessing previously unreachable reserves. Mechanical engineers have developed:

- Horizontal and Directional Drilling: These techniques allow operators to reach oil deposits that are not directly below the drilling site. Mechanical innovations in drill bit design and steering mechanisms have made it possible to navigate through various geological formations with precision.

- Robotics and Automation: The integration of robotics in drilling operations reduces human exposure to hazardous environments and increases efficiency. Automated drilling systems enhance precision and speed, leading to cost savings and improved safety records.

- Advanced Materials: The development of high-strength, corrosion-resistant materials for drill pipes and bits extends the life of equipment and reduces maintenance costs. These materials can withstand extreme temperatures and pressures encountered during deep drilling operations.

Enhancements in Pumping and Lifting Systems

Efficient extraction of oil relies heavily on effective pumping and lifting mechanisms. Mechanical engineers have contributed significantly through:

- Artificial Lift Systems: Innovations such as Electric Submersible Pumps (ESPs) and Progressive Cavity Pumps (PCPs) have evolved to handle a variety of reservoir conditions. ESPs, in particular, have seen mechanical improvements that allow for higher temperature and pressure tolerances.

- Gas Lift Techniques: Mechanical modifications in gas lift valves and mandrels have improved the injection and distribution of lift gas, enhancing the efficiency of the lifting process.

- Enhanced Rod Pump Designs: Modern rod pumps incorporate advanced mechanics to reduce friction and wear, increasing longevity, and reducing operational costs.

Advanced Well Stimulation and Completion Techniques

Mechanical engineering has also transformed well stimulation and completion practices:

- Hydraulic Fracturing Advances: Mechanical innovations in fracturing equipment, like high-pressure pumps and proppant delivery systems, have made hydraulic fracturing more efficient and controlled.

- Multistage Fracturing Systems: Mechanical engineers have developed tools that allow for multiple fracturing stages in horizontal wells, optimizing the stimulation process and enhancing oil recovery.

- Intelligent Completion Systems: Incorporating mechanical devices that can be adjusted from the surface allows for better control over the production zones, leading to improved recovery rates and reduced water or gas intrusion.

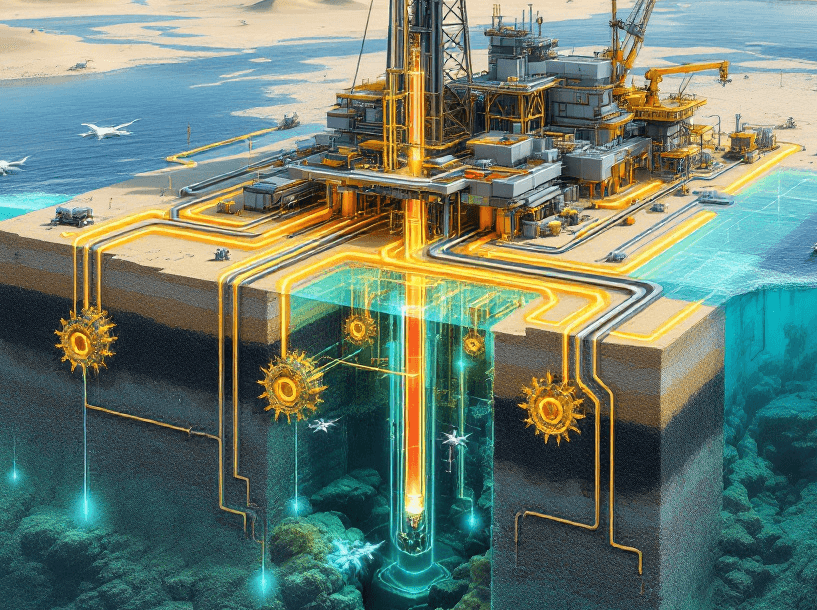

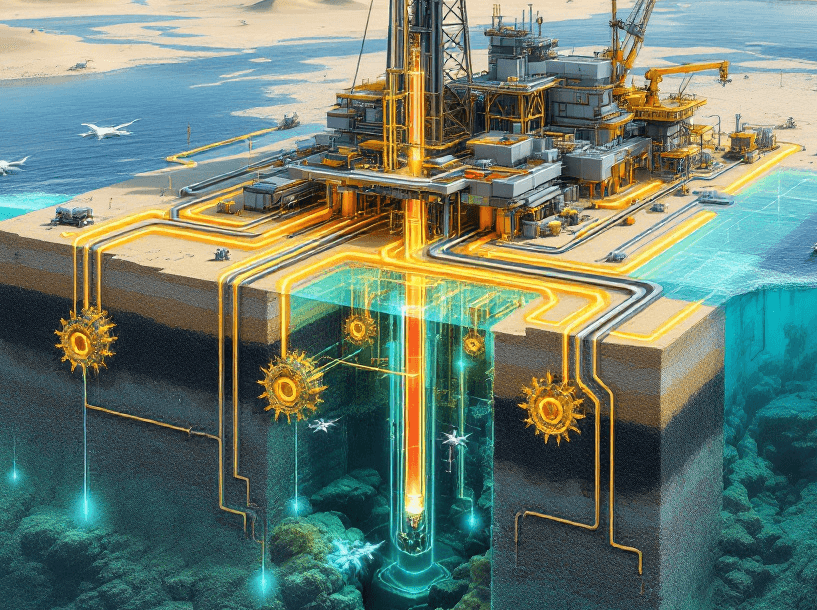

Subsea Engineering and Deepwater Technologies

The move towards offshore and deepwater drilling presents unique mechanical challenges:

- Subsea Production Systems: Mechanical engineers have developed robust subsea equipment, including blowout preventers, manifolds, and control systems, designed to operate reliably under high pressures and low temperatures.

- Riser Technologies: Innovations in riser designs accommodate the movement of floating platforms while maintaining the integrity of the connection between the subsea well and the surface facilities.

- Flow Assurance: Mechanical solutions address issues like hydrate formation and wax deposition in pipelines, ensuring the continuous and efficient flow of hydrocarbons.

Monitoring and Maintenance Technologies

Maintenance and monitoring are critical for the longevity and safety of oil recovery operations:

- Sensors and Monitoring Devices: Mechanical engineers have integrated advanced sensors into equipment to provide real-time data on operational parameters, enabling proactive maintenance and immediate response to issues.

- Predictive Maintenance: Utilizing mechanical data analytics, operators can predict equipment failures before they occur, reducing downtime and maintenance costs.

- Robotic Inspection Tools: Robots and drones equipped with mechanical diagnostic tools inspect equipment in hazardous areas without risking human life.

Material Science Integration

Material science developments directly impact mechanical engineering solutions:

- High-performance Alloys and Composites: New materials resistant to corrosion and capable of withstanding extreme conditions improve the durability and reliability of mechanical components.

- Elastomers and Seals: Advanced mechanical designs of seals and gaskets prevent leaks and withstand a wide range of temperatures and pressures, crucial for maintaining equipment integrity.

- Coatings and Treatments: Mechanical components benefit from surface treatments that reduce friction and wear, enhancing performance and extending service life.

Future Trends in Mechanical Engineering for EOR

The future of mechanical engineering in enhanced oil recovery is poised to embrace cutting-edge technologies:

- Nanotechnology Applications: Nanomaterials can improve the mechanical properties of equipment, offering superior strength and flexibility. Nanorobots might one day be used for reservoir characterization and modification.

- Additive Manufacturing (3D Printing): The ability to print mechanical components on-site reduces lead times and allows for the customization of parts to specific operational needs.

- Internet of Things (IoT): Connecting mechanical systems through IoT enables smarter operations, where equipment can adjust in real-time to changing conditions, improving efficiency and reducing risk.

Conclusion

Mechanical engineering innovations are at the forefront of advancing enhanced oil recovery techniques. By improving drilling technologies, refining pumping and lifting systems, and integrating advanced materials and monitoring systems, mechanical engineers are enabling the oil and gas industry to extract resources more effectively and efficiently than ever before. As the industry faces new challenges in accessing difficult reserves and operating under stringent environmental regulations, the role of mechanical engineering will continue to be crucial. Embracing future technologies such as nanotechnology, additive manufacturing, and IoT will further enhance oil recovery methods, ensuring that the industry can meet global energy demands sustainably and responsibly.