The oil and gas industry has long been a cornerstone of global energy supply, fueling economies and enabling modern lifestyles. However, it is also a significant contributor to greenhouse gas emissions, particularly carbon dioxide (CO₂). As the world intensifies efforts to combat climate change, reducing these emissions has become a critical focus. One of the most promising strategies is Carbon Capture and Storage (CCS), a technology that captures CO₂ emissions from industrial sources and stores them underground to prevent them from entering the atmosphere. This article explores the latest developments in CCS technologies within the oil and gas sector, highlighting innovations that are driving the industry towards a more sustainable future.

The Role of Carbon Capture and Storage in the Oil and Gas Industry

Understanding Carbon Capture and Storage

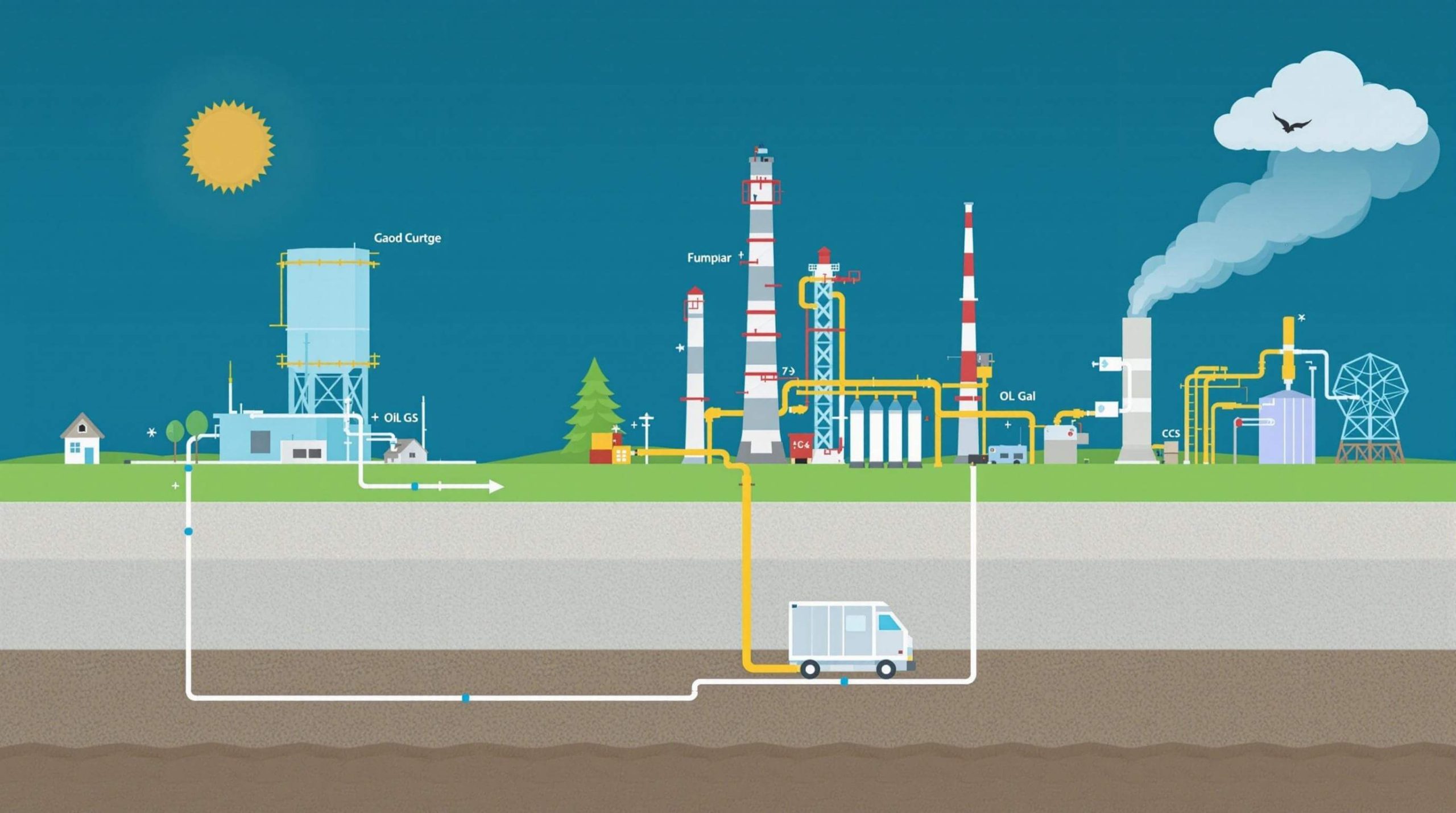

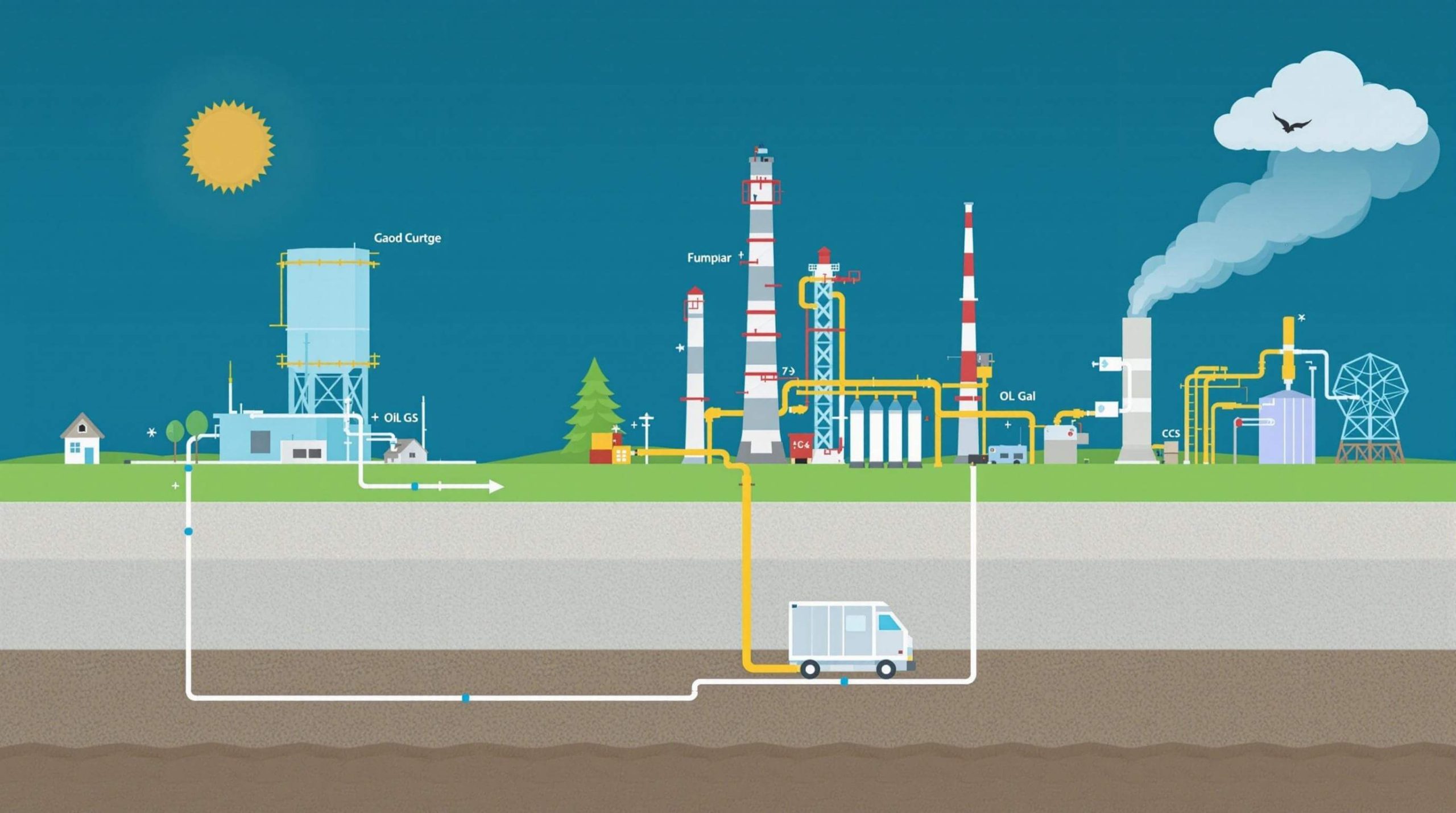

Carbon Capture and Storage involves three main steps:

- Capture: CO₂ is separated from other gases produced at large industrial facilities such as power plants, refineries, and chemical plants.

- Transport: The captured CO₂ is compressed and transported, typically via pipelines, to storage sites.

- Storage: CO₂ is injected deep underground into geological formations, where it is securely stored.

Why CCS is Crucial for Emissions Reduction

CCS is essential for mitigating climate change for several reasons:

- Emissions Reduction: It directly reduces CO₂ emissions from industrial sources.

- Economic Viability: Allows continued use of fossil fuels while reducing environmental impact.

- Energy Security: Balances the need for reliable energy with environmental concerns.

- Technological Synergy: Integrates with existing industrial processes and infrastructure.

Latest Developments in Carbon Capture Technologies

Advancements in Capture Methods

Solvent-Based Capture

Traditional solvent-based systems use chemical solvents like amines to absorb CO₂. Recent innovations include:

- Advanced Solvents: Development of new solvents with higher CO₂ absorption capacity and lower energy requirements.

- Solid Sorbents: Use of solid materials that can capture CO₂ more efficiently and are easier to regenerate.

Membrane Technologies

Membrane separation uses selective barriers to separate CO₂ from gas mixtures.

- Polymeric Membranes: Improved polymers with higher permeability and selectivity for CO₂.

- Hybrid Membrane Systems: Combining membranes with other technologies (e.g., absorption) to enhance efficiency.

Cryogenic Processes

Cryogenic capture involves cooling gases to low temperatures to separate CO₂.

- Enhanced Cryogenics: Development of processes that reduce energy consumption and improve CO₂ purity.

- Cryocapture Systems: Integrated systems that combine cryogenics with renewable energy sources.

Carbonate Fuel Cells

An emerging technology where fuel cells capture CO₂ while generating electricity.

- Dual Benefit: Simultaneous carbon capture and power generation increases overall efficiency.

- Scalability: Potential for integration into existing power plants and industrial facilities.

Innovations in Carbon Utilization

Carbon-to-Value Technologies

Converting captured CO₂ into valuable products:

- Synthetic Fuels: Using CO₂ to produce methanol, ethanol, or other synthetic fuels.

- Chemicals and Materials: Production of polymers, carbonates, and other industrial chemicals.

- Enhanced Oil Recovery (EOR): Injecting CO₂ into oil reservoirs to improve extraction rates.

Bioenergy with Carbon Capture and Storage (BECCS)

Combining biomass power generation with CCS:

- Negative Emissions: BECCS can result in net removal of CO₂ from the atmosphere.

- Sustainable Feedstocks: Utilizes waste biomass, reducing competition with food crops.

Advancements in Carbon Storage Technologies

Geological Storage Innovations

Enhanced Reservoir Characterization

Improved understanding of storage sites ensures safe and effective CO₂ storage.

- Seismic Imaging: Advanced seismic techniques to map subsurface formations.

- Reservoir Simulation: High-resolution models predict CO₂ behavior underground.

Monitoring and Verification Technologies

Ensuring the integrity of storage sites:

- Satellite Monitoring: Remote sensing to detect surface changes.

- Fiber Optic Sensing: Real-time monitoring of pressure and temperature in wells.

Mineralization and Solid Storage

Converting CO₂ into stable minerals:

- Accelerated Mineralization: Processes that speed up natural reactions between CO₂ and rocks.

- Carbonate Formation: Creating solid carbonates for long-term storage.

Policy and Regulatory Support for Storage

Governments are introducing incentives and legal frameworks:

- Tax Credits: Financial incentives for companies that implement CCS projects.

- Liability Frameworks: Clear regulations on long-term responsibility for stored CO₂.

Case Studies of Recent CCS Projects

The Petra Nova Project

- Location: Texas, USA

- Innovation: One of the largest post-combustion carbon capture projects, capturing CO₂ from a coal-fired power plant for EOR.

- Impact: Demonstrated the viability of large-scale CCS in the power sector.

The Quest CCS Project

- Location: Alberta, Canada

- Innovation: Captures CO₂ from hydrogen production in oil sands upgrading.

- Impact: Over 6 million tonnes of CO₂ stored since 2015, providing valuable operational data.

Northern Lights Project

- Location: Offshore Norway

- Innovation: A full-scale CCS value chain designed to store CO₂ from various European industrial sources.

- Impact: Pioneering cross-border CO₂ transport and storage solutions.

Gorgon CO₂ Injection Project

- Location: Western Australia

- Innovation: Injects CO₂ removed from natural gas processing into deep geological formations.

- Impact: Aims to reduce emissions by approximately 100 million tonnes over the project’s lifetime.

Challenges and Opportunities

Technical Challenges

- Energy Requirements: CCS processes can be energy-intensive, reducing net efficiency.

- Scale-Up: Moving from pilot projects to full-scale operations is complex.

- Integration: Ensuring seamless integration with existing industrial systems.

Economic Considerations

- High Initial Costs: Significant capital investment needed for CCS infrastructure.

- Market Incentives: Need for carbon pricing or subsidies to make CCS economically viable.

- Financing Models: Developing partnerships between governments and industry.

Regulatory and Policy Landscape

- Legal Frameworks: Clear guidelines for CO₂ transport and storage are needed.

- Public Acceptance: Addressing concerns about safety and environmental impact.

- International Cooperation: Harmonizing policies to facilitate cross-border CCS projects.

Future Opportunities

- Technological Innovation: Continued R&D can reduce costs and improve efficiency.

- Carbon Markets: Expanding carbon trading can provide financial incentives.

- Climate Goals Alignment: CCS is critical for achieving net-zero emissions targets.

Conclusion

Carbon Capture and Storage represents a pivotal technology in the global effort to reduce greenhouse gas emissions, particularly within the oil and gas industry. Recent innovations have significantly advanced both the capture and storage components, making CCS more efficient, cost-effective, and scalable. Projects around the world are demonstrating the practical viability of CCS, contributing valuable insights and pushing the boundaries of what’s possible.

Despite challenges, the combination of technological advancements, supportive policies, and economic incentives is creating a favorable environment for CCS deployment. As industries and governments strive to meet ambitious climate goals, CCS will play an increasingly vital role. By embracing these innovations, the oil and gas industry can significantly reduce its carbon footprint while continuing to provide the energy resources essential for modern society.