Oil and gas reservoirs are complex geological formations that hold vast amounts of hydrocarbons. However, extracting these resources efficiently and economically poses significant challenges. While primary and secondary recovery methods tap into a portion of the reservoir’s potential, a substantial amount of oil often remains trapped. This is where Enhanced Oil Recovery (EOR) techniques come into play, offering innovative solutions to maximize reservoir output and extend the life of oil fields.

Enhanced Oil Recovery refers to a set of technologies aimed at increasing the amount of crude oil that can be extracted from an oil reservoir. While primary recovery relies on the natural pressure of the reservoir, and secondary recovery utilizes external forces like water injection, EOR techniques involve altering the properties of the oil, rock, or reservoir conditions to improve extraction efficiency.

Despite advancements in drilling and production technologies, conventional methods typically recover only about 20-40% of the original oil in place (OOIP). This leaves a significant portion of the resource untapped. EOR techniques are essential for:

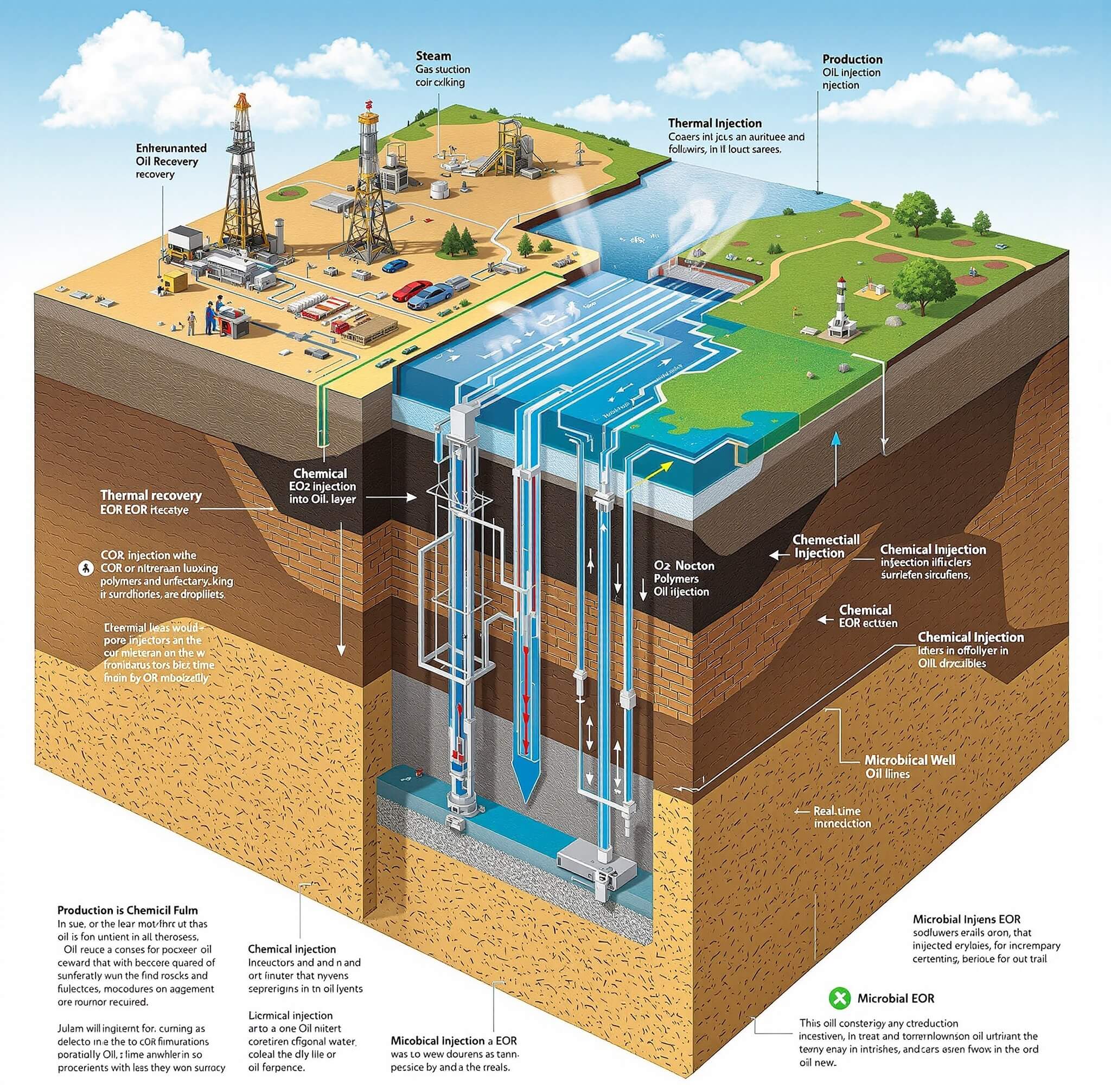

EOR methods are generally categorized into three main types: thermal recovery, gas injection, and chemical injection. Each technique aims to overcome the challenges of oil viscosity, reservoir heterogeneity, and other factors that impede oil flow.

Steam injection is the most common thermal EOR method. It involves introducing steam into the reservoir to reduce the viscosity of heavy oils, making them easier to produce.

In this process, a portion of the oil is ignited within the reservoir, generating heat that reduces the viscosity of the remaining oil.

Miscible gas injection involves injecting gases like carbon dioxide (CO2), natural gas, or nitrogen into the reservoir. The gas mixes with the oil, reducing its viscosity and swelling it, which enhances flow.

In cases where the gas does not mix with the oil, it helps to maintain reservoir pressure and displace the oil towards production wells.

Involves injecting water-soluble polymers to increase the viscosity of the injected water, improving sweep efficiency and pushing more oil towards production wells.

Combines surfactants and polymers to reduce interfacial tension between oil and water, mobilizing trapped oil droplets.

A more complex method that adds alkaline chemicals to the surfactant-polymer mixture, enhancing oil recovery by saponification reactions that produce natural surfactants within the reservoir.

MEOR utilizes microorganisms or their metabolites to mobilize oil. Bacteria can produce gases, solvents, or surfactants that reduce oil viscosity or interfacial tension.

The use of nanoparticles to alter reservoir properties, enhance oil mobility, or improve sweep efficiency.

Adjusting the ionic composition of injected water to improve oil recovery by altering wettability.

Tailoring the composition of injection water to interact with reservoir rock and fluids for enhanced recovery.

Choosing the appropriate EOR technique depends on various factors:

Comprehensive analysis of the reservoir to understand its properties and predict the performance of different EOR methods.

Conducting small-scale field tests to validate laboratory findings and optimize process parameters.

Upon successful pilot results, scaling up operations to implement the EOR method across the reservoir.

Continuous monitoring of reservoir performance and adjusting operational parameters to maximize recovery.

Advancements in technology, data analytics, and a better understanding of reservoir dynamics are driving the evolution of EOR methods.

As EOR projects can have significant environmental impacts, it’s crucial to address:

Enhanced Oil Recovery techniques play a pivotal role in maximizing reservoir output and ensuring the sustainable development of oil resources. By carefully selecting and implementing the appropriate EOR methods, operators can unlock additional reserves, extend the life of oil fields, and contribute to meeting global energy demands. As the industry progresses, continued innovation and responsible practices will be essential in harnessing the full potential of EOR technologies.

The primary goal of EOR is to increase the amount of crude oil that can be extracted from an oil reservoir beyond what is possible with primary and secondary recovery methods.

Thermal recovery methods, such as steam injection and in-situ combustion, are most effective for heavy oil reservoirs due to their ability to reduce oil viscosity.

CO2 injection enhances oil recovery by mixing with the oil, reducing its viscosity, and causing it to swell, which improves flow and displacement towards production wells.

EOR techniques can reduce the need for new oil field developments, minimizing environmental disruption. Methods like CO2 injection also aid in carbon sequestration, mitigating greenhouse gas emissions.

Challenges include the high cost of chemicals, potential formation damage, scaling issues, and the need for compatible chemicals that suit specific reservoir conditions.

By integrating advanced Enhanced Oil Recovery techniques, the oil and gas industry can significantly improve production efficiency and sustainability. It’s essential to stay informed about these methods to make strategic decisions that align with both economic goals and environmental responsibilities.