Introduction: The Non-Negotiable Importance of SIL Verification

The catastrophic legacy of Bhopal, Flixborough, and Texas City refinery explosions underscores a brutal truth: functional safety failures in the oil and gas industry carry human, environmental, and financial costs too grave to ignore. At the heart of preventing such disasters lies Safety Instrumented Systems (SIS), whose performance hinges on rigorous Safety Integrity Level (SIL) verification. This complex but critical process ensures that Safety Instrumented Functions (SIFs) will operate with the required reliability when process conditions veer toward catastrophe. For engineers grappling with standards like IEC 61511 and ISA-84, ISA-TR84.00.02 emerges as an indispensable guide for navigating SIL verification’s quantitative and qualitative demands. This article demystifies SIL verification by translating ISA-TR84.00.02’s methodology into actionable steps, addresses pervasive industry pitfalls, and empowers you to build safer, standards-compliant facilities 39.

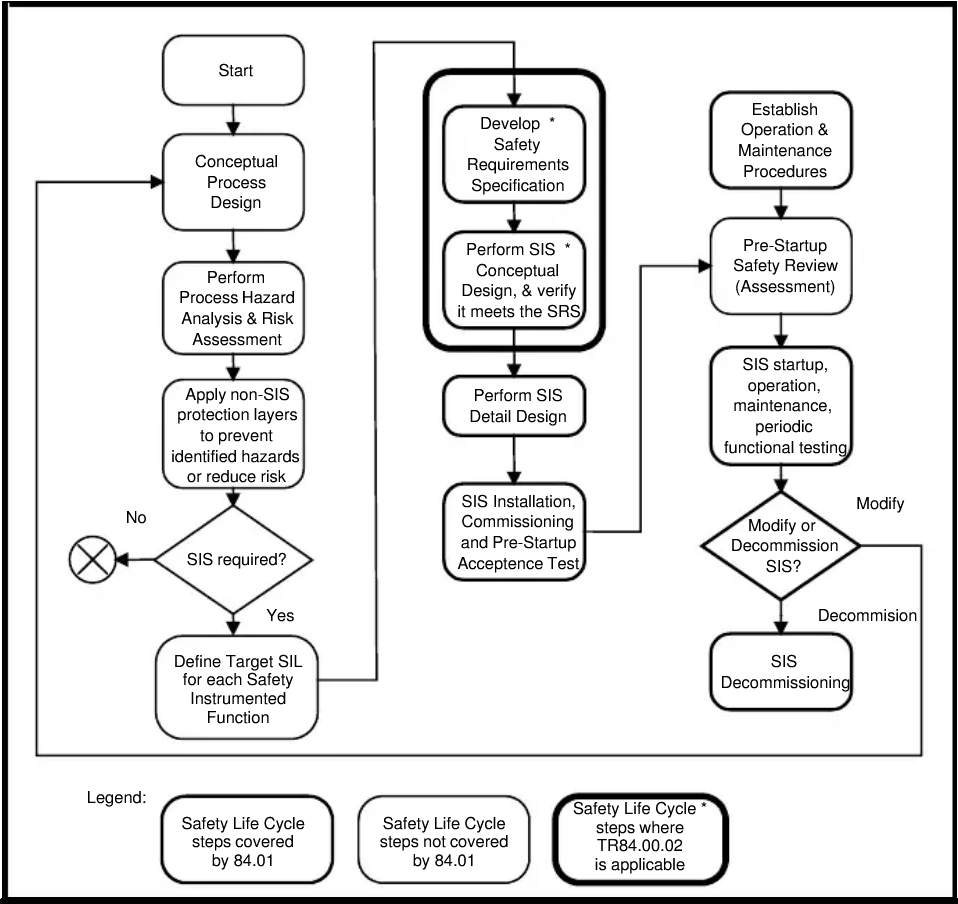

SIL verification is not a standalone activity but a pivotal step within the functional safety lifecycle mandated by IEC 61511 and ANSI/ISA-84.00.01. It occurs after SIL determination (e.g., via LOPA) and before final system validation and operation.

Core Objectives:

For existing facilities, ISA-TR84.00.02 acknowledges the “grandfather clause” (ANSI/ISA-84.00.01), but stresses that verification remains essential for proving ongoing compliance and managing modification impacts 3.

Developed by the ISA84 committee, this technical report (TR) provides methodologies to implement IEC 61511’s quantitative verification requirements. Unlike the standard itself, ISA-TR84.00.02 is informative, not normative—yet it’s widely regarded as industry best practice.

Oil & Gas Context: Offshore platforms, refineries, and pipelines often use partial valve stroke testing (PVST) for online verification. ISA-TR84.00.03 (mechanical integrity) supplements this TR for such applications 3.

Use formulas for subsystem architectures. For a 1oo2 sensor subsystem:

math

PFD_{avg} ≈ \frac{(λ_{DU} \cdot TI)^2}{3} + \frac{(λ_{DD} \cdot MTTR)}{2} + \frac{(λ_{DU} \cdot β \cdot TI)}{2}

Key considerations:

Table: Common SIF Architectures and PFDavg Approximations

| Architecture | PFDavg Approximation | Typical Use Case |

|---|---|---|

| 1oo1 | λ<sub>DU</sub> × TI / 2 | Single pressure switch |

| 1oo2 | [(λ<sub>DU</sub> × TI)<sup>2</sup>]/3 | Redundant gas detectors |

| 2oo3 | [(λ<sub>DU</sub> × TI)<sup>2</sup>] | Critical pressure transmitters |

Verify subsystems meet minimum hardware fault tolerance (HFT) using Route 1H/2H tables. For example:

Use reliability block diagrams to model spurious trips. For a 1oo2 system:

math

MTTFS = \frac{1}{λ_{Total\_Spurious}} \quad where \quad λ_{Total} = λ_{SD} + λ_{SU} + (β \cdot λ_{DD})

Operational Impact: High spurious trip rates in LNG facilities can cost >$1M/hour in lost production 11.

Scenario: Overpressure protection (SIL 2) for a crude oil separator.

Original Design:

Redesign per ISA-TR84.00.02:

Risk: Inflated C<sub>PT</sub> values (e.g., 90% vs. actual 60%) artificially lower PFDavg.

Fix: Document test procedures rigorously. Use residual risk factors (RRF) for coverage gaps 4.

Risk: Identical redundant devices failing simultaneously (e.g., plugged impulse lines on redundant PTs).

Fix: Apply beta factors ≥5% for identical sensors/valves. Use diversity (e.g., pressure + flow for overfill protection) 11.

Risk: Manual valves left in bypass post-maintenance.

Fix: Include bypass probability in PFDavg models and enforce procedural controls 9.

Risk: Using PFDavg for compressor anti-surge controls (high-demand mode).

Fix: Use PFH (Probability of Failure per Hour) calculations for >1 demand/year 4.

Software Solutions: Tools like SILcet automate PFDavg/PFH calculations using ISA-TR84.00.02 methods and integrate:

Best Practices:

SIL verification transcends compliance paperwork—it’s the engineering bedrock of trustworthy safety systems. In the high-hazard landscape of oil and gas, ISA-TR84.00.02 provides the methodological clarity needed to navigate PFDavg calculations, architectural constraints, and operational realities. Yet, its true value emerges only when paired with site-specific data, uncompromising testing, and cross-functional collaboration between process safety, instrumentation, and maintenance teams. By demystifying SIL verification and confronting its pitfalls head-on, engineers can transform abstract standards into tangible barriers against catastrophe—ensuring that when the unthinkable happens, the SIF responds 3911.

Takeaway: Start your next SIL verification with three questions:

- “Is my failure data relevant to this specific service?”

- “Could my proof tests miss critical failure modes?”

- “What’s the cost of a spurious trip—and is my MTTFS acceptable?”

References & Further Reading: