Offshore oil production plays a pivotal role in meeting the world’s energy demands. As global consumption continues to rise, tapping into underwater oil reserves has become increasingly essential. However, this pursuit comes with significant environmental risks that can have lasting impacts on marine ecosystems. Mitigating these risks is crucial to ensure sustainable energy production while preserving the health of our oceans. This article outlines the environmental challenges associated with offshore drilling and explores the strategies employed to minimize their impact.

One of the most significant environmental risks in offshore oil production is the potential for oil spills and leaks. Accidents like blowouts or pipeline ruptures can release vast quantities of oil into the ocean, causing widespread damage to marine life, coastal habitats, and local economies reliant on fishing and tourism. The Deepwater Horizon spill in 2010, for instance, released millions of barrels of oil into the Gulf of Mexico, highlighting the catastrophic consequences of such incidents.

During drilling operations, various discharges occur, including drilling muds and cuttings. These materials can contain hydrocarbons and heavy metals that, if not properly managed, may contaminate the seabed and surrounding waters. Such contamination can harm benthic organisms and disrupt the food chain.

Operational discharges refer to the release of produced water—water that comes up with the oil and gas—which often contains salts, hydrocarbons, and other chemicals. If discharged untreated, this water can negatively impact marine environments.

Offshore platforms emit pollutants into the atmosphere, including volatile organic compounds (VOCs), nitrogen oxides (NOx), sulfur oxides (SOx), and greenhouse gases like carbon dioxide (CO₂). These emissions contribute to air pollution and climate change, posing broader environmental challenges.

The construction and presence of offshore infrastructure can physically disturb marine habitats. The installation of platforms, pipelines, and subsea equipment may damage coral reefs, seagrass beds, and other sensitive environments. Additionally, anchoring and dredging activities can lead to sedimentation that smothers marine life.

Seismic surveys and the operation of heavy machinery generate underwater noise that can affect marine mammals and fish. Noise pollution can disrupt communication, navigation, and feeding patterns, leading to stress or displacement of marine species.

Offshore operations generate solid and hazardous wastes, including chemical containers, maintenance waste, and obsolete equipment. Improper disposal of these wastes can lead to pollution and harm to marine organisms.

Mitigating the environmental risks of offshore oil production requires a combination of advanced technologies, stringent regulations, and proactive management practices. Below are some key strategies employed by the industry.

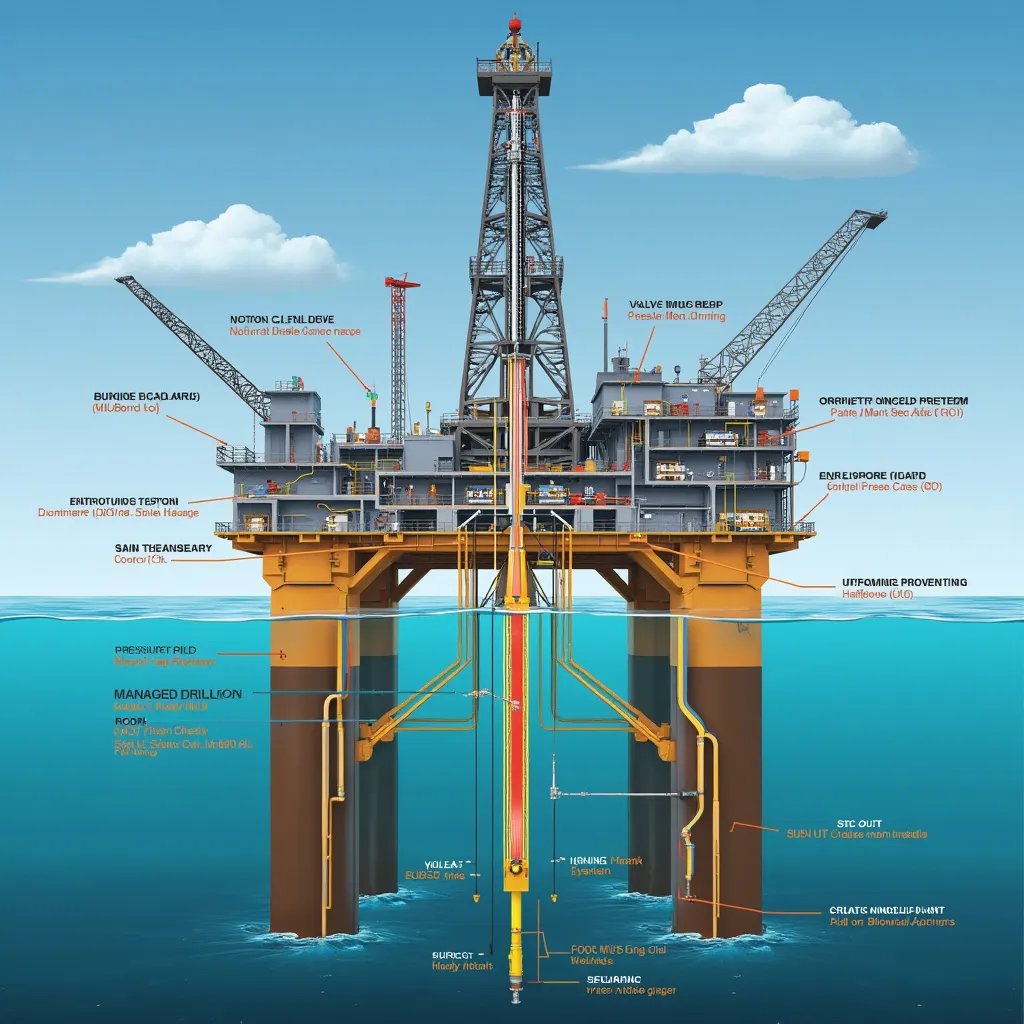

Blowout preventers are critical safety devices installed at the wellhead to prevent uncontrolled releases of oil and gas. Modern BOPs are equipped with multiple fail-safes and redundant systems to ensure they can seal the well in case of emergencies.

Managed Pressure Drilling techniques allow for precise control of wellbore pressures, reducing the likelihood of kicks and blowouts. MPD enhances drilling safety and minimizes the risk of spills.

Operators are required to develop comprehensive oil spill response plans outlining the actions to be taken in the event of a spill. These plans include the deployment of containment booms, skimmers, and dispersants to mitigate the spread of oil.

Maintaining readily available response equipment and trained personnel ensures a rapid reaction to incidents, minimizing environmental impacts.

Implementing Environmental Management Systems (EMS) based on international standards like ISO 14001 helps companies systematically manage their environmental responsibilities. An EMS enables continuous improvement in environmental performance through regular monitoring and evaluation.

Adopting zero discharge policies for certain wastes prevents harmful materials from entering the marine environment. Instead, wastes are transported to shore for proper treatment and disposal.

By reducing waste generation and promoting recycling, companies can lessen their environmental footprint. Efficient use of materials and resources also leads to cost savings.

Replacing oil-based drilling muds with water-based or synthetic alternatives reduces the toxicity of drilling discharges. These fluids are less harmful to marine life if released into the environment.

Robust well design, incorporating multiple barriers and high-quality materials, ensures structural integrity and reduces the risk of leaks throughout the well’s life.

Compliance with international agreements like the International Convention for the Prevention of Pollution from Ships (MARPOL) and regional agreements such as the OSPAR Convention in the North-East Atlantic sets a benchmark for environmental protection.

Adhering to stringent national regulations governing offshore operations ensures that environmental risks are minimized. Regulatory agencies often require environmental impact assessments and regular reporting.

Continuous monitoring of environmental parameters allows for early detection of potential impacts. Monitoring programs assess water quality, sediment composition, and biological communities around offshore installations.

Prior to commencing operations, environmental impact assessments (EIAs) identify potential risks and outline mitigation measures. EIAs involve public consultation and help inform decision-making processes.

Engaging with stakeholders, including local communities, NGOs, and governments, promotes transparency and builds trust. By openly communicating environmental performance and incident reports, companies demonstrate their commitment to responsible operations.

Norway is renowned for its stringent environmental standards in offshore oil production. The country has implemented comprehensive regulations that require operators to employ best available techniques and continuously reduce emissions and discharges. Norwegian companies utilize advanced technology, such as subsea separation and injection, to minimize surface impacts.

FPSOs allow for the processing and storage of oil offshore, reducing the need for extensive pipeline networks that can disturb the seafloor. They are equipped with advanced safety and environmental protection systems, including gas flaring reduction technologies.

Technological innovation is key to further mitigating environmental risks. Research and development efforts focus on:

The global demand for energy necessitates continued exploration and production of oil and gas resources. However, this must be balanced with the responsibility to protect the environment. Companies are increasingly adopting sustainable practices, driven by regulatory requirements, stakeholder expectations, and a growing recognition of the importance of environmental stewardship.

Many oil and gas companies now publish sustainability reports detailing their environmental performance and targets. Such transparency holds companies accountable and encourages continuous improvement.

While oil and gas remain essential, there is a gradual shift towards integrating renewable energy sources. Some offshore platforms are powered by wind or solar energy, reducing their carbon footprint.

Mitigating environmental risks in offshore oil production is a complex but essential task. Through the adoption of advanced technologies, strict adherence to regulations, and a commitment to environmental management, the industry can significantly reduce its impact on marine ecosystems. Continuous innovation and stakeholder engagement are critical to achieving sustainable offshore operations. By balancing energy production with environmental protection, we can ensure that the benefits of offshore oil extraction do not come at the expense of our oceans’ health.

By prioritizing environmental risk mitigation, the offshore oil industry demonstrates its commitment to sustainable practices. Ongoing efforts to enhance safety, minimize pollution, and protect marine life are essential for the industry’s future viability and the well-being of the planet.