The oil and gas industry is a cornerstone of the global energy supply, driving economic growth and providing vital resources for various industries. However, its infrastructure—from sprawling extraction sites to intricate distribution networks—poses significant environmental and economic challenges throughout its lifecycle. A comprehensive lifecycle analysis (LCA) of oil and gas infrastructure examines these impacts from construction through operation to decommissioning, offering insights into sustainability and cost-effectiveness. This article delves into the environmental and economic aspects at each stage, highlighting the importance of integrating LCA in strategic planning.

Understanding Lifecycle Analysis in Oil and Gas

Lifecycle analysis is a systematic approach to assessing the environmental aspects and potential impacts associated with a product, process, or service. In the context of oil and gas infrastructure, LCA evaluates the cumulative effects of infrastructure projects, helping stakeholders make informed decisions that balance economic benefits with environmental stewardship.

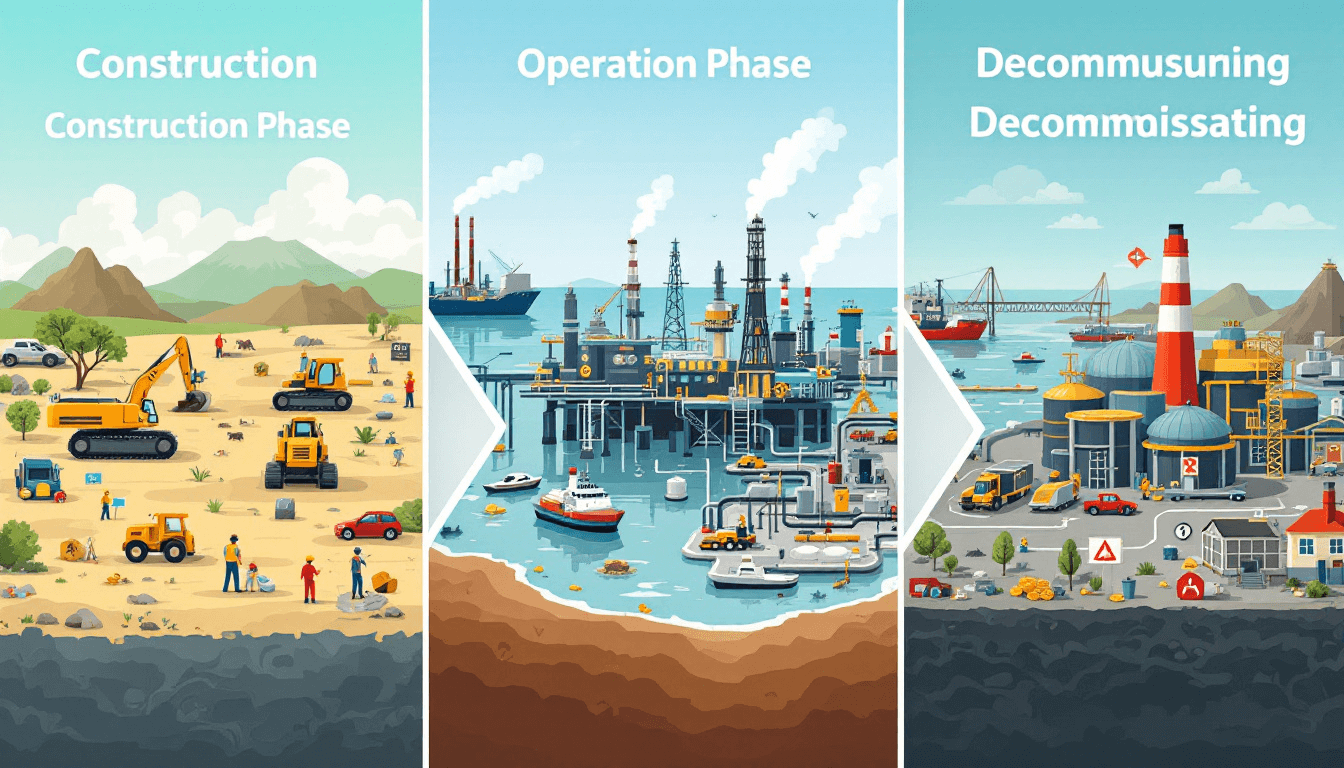

1. Construction Phase

Environmental Aspects

The construction of oil and gas infrastructure involves significant environmental disruptions. Land clearing for drilling sites, pipelines, and facilities leads to habitat destruction and biodiversity loss. Soil erosion and sedimentation can affect nearby water bodies, while the use of heavy machinery contributes to air and noise pollution. Additionally, the production and transportation of construction materials generate greenhouse gas (GHG) emissions.

Economic Aspects

Financially, the construction phase requires substantial capital investment. Costs include procurement of materials, labor, equipment, and compliance with regulatory requirements. Delays due to environmental assessments or community opposition can inflate budgets. However, construction activities can stimulate local economies through job creation and demand for local services.

2. Operation Phase

Environmental Aspects

During operation, oil and gas infrastructure can have ongoing environmental impacts. Routine emissions of volatile organic compounds (VOCs), methane leaks, and flaring contribute to air pollution and climate change. The risk of oil spills or gas leaks poses threats to ecosystems and water resources. Moreover, the consumption of large volumes of water for processes like hydraulic fracturing can strain local water supplies.

Economic Aspects

Operational efficiency directly influences profitability. Operational costs include maintenance, labor, energy consumption, and compliance with environmental regulations. Efficient operations can extend the lifespan of infrastructure and improve return on investment. However, operational disruptions due to environmental incidents can result in significant financial losses and reputational damage.

3. Decommissioning Phase

Environmental Aspects

Decommissioning involves dismantling infrastructure and restoring sites, which can mitigate long-term environmental impacts. Proper disposal of hazardous materials, site remediation, and habitat restoration are critical. Failure to decommission properly can leave lasting environmental legacies, such as soil contamination and abandoned equipment.

Economic Aspects

The decommissioning phase entails considerable costs. Financial planning for decommissioning is essential to ensure that funds are available when needed. Costs include deconstruction, waste management, site remediation, and regulatory compliance. However, there are opportunities to recycle materials and repurpose sites, which can offset some expenses.

Integrating Environmental and Economic Considerations

Balancing environmental responsibility with economic viability is crucial. Implementing sustainable practices can reduce environmental impacts and lead to cost savings. For instance, adopting technologies that minimize emissions or improve energy efficiency can lower operational costs and mitigate environmental risks.

Regulatory Framework and Compliance

Regulatory compliance plays a significant role throughout the infrastructure lifecycle. Environmental regulations may require impact assessments, emission controls, and decommissioning plans. Non-compliance can result in fines, legal action, and project delays, affecting the economic bottom line.

Advancements in Sustainable Technologies

Technological innovations offer pathways to reduce environmental impacts and improve economic outcomes. Examples include:

Case Studies

Case Study 1: Offshore Oil Rig Decommissioning

An offshore oil rig in the North Sea underwent decommissioning with a focus on environmental restoration. By planning early and engaging with environmental experts, the company minimized ecological impacts and recycled a significant portion of the materials, reducing costs.

Case Study 2: Pipeline Construction Optimization

A pipeline project in North America implemented directional drilling to avoid sensitive ecosystems. Although the initial costs were higher, the approach prevented environmental damage and potential legal challenges, ultimately saving money in the long term.

Conclusion

A lifecycle analysis of oil and gas infrastructure reveals that environmental and economic aspects are deeply intertwined. By considering the cumulative impacts from construction to decommissioning, stakeholders can identify strategies to mitigate negative effects while enhancing economic performance. Embracing sustainable practices, adhering to regulations, and leveraging technological advancements are essential steps toward a more responsible and profitable oil and gas industry.