The oil and gas industry is pivotal to the global economy, providing energy and raw materials essential for modern life. However, it is also one of the largest contributors to greenhouse gas emissions, particularly carbon dioxide (CO2), which exacerbate climate change. Carbon Capture and Storage (CCS) emerges as a critical technology in mitigating these emissions, enabling the industry to reduce its carbon footprint significantly.

In this article, we explore the various technologies and methods employed in capturing and storing carbon emissions from oil and gas operations. Understanding these technologies is essential for industry stakeholders aiming to balance energy demands with environmental stewardship.

The Importance of Carbon Capture and Storage (CCS)

CCS refers to the process of capturing CO2 emissions produced from industrial processes, transporting them to a storage site, and depositing them where they will not enter the atmosphere, typically in underground geological formations. The implementation of CCS is vital for several reasons:

- Environmental Protection: Reduces the amount of CO2 released into the atmosphere, combating climate change.

- Regulatory Compliance: Helps companies meet emission targets set by governments and international agreements.

- Economic Benefits: Opens avenues for enhanced oil recovery and other industrial applications of captured CO2.

Technologies for Capturing Carbon Emissions

Capturing CO2 is the first step in the CCS process. The primary technologies used in the oil and gas industry for carbon capture are:

Pre-Combustion Capture

Pre-combustion capture involves removing CO2 before the combustion process. This method is commonly used in gasification plants where fuel is converted into a mixture of hydrogen and carbon monoxide (syngas). The steps include:

- Gasification: Coal or natural gas is converted into syngas.

- Shift Reaction: Syngas reacts with steam to produce hydrogen and CO2.

- CO2 Separation: CO2 is separated from hydrogen using physical or chemical absorption methods.

Advantages:

- Produces hydrogen that can be used as a clean fuel.

- High CO2 concentration makes separation more efficient.

Challenges:

- Requires significant modifications to existing plants.

- High initial capital investment.

Post-Combustion Capture

Post-combustion capture is the most straightforward method to integrate into existing power plants. It involves capturing CO2 from flue gases after the combustion of fossil fuels.

Techniques Used:

- Chemical Absorption: Using solvents like amine solutions to absorb CO2.

- Physical Adsorption: Employing materials like activated carbon.

- Membrane Separation: Using selective membranes to separate CO2 from other gases.

Advantages:

- Can be retrofitted to existing plants.

- Mature technology with extensive research backing.

Challenges:

- Low CO2 concentration in flue gases requires more energy for capture.

- Degradation of solvents can lead to operational issues.

Oxy-Fuel Combustion

Oxy-fuel combustion involves burning fossil fuels in oxygen instead of air, resulting in a flue gas that is mainly water vapor and CO2, which can be easily separated.

Process:

- Air Separation: Oxygen is separated from nitrogen in the air.

- Combustion: Fuel is burned in pure oxygen, producing a CO2-rich flue gas.

- CO2 Capture: The water vapor is condensed, leaving concentrated CO2.

Advantages:

- High purity CO2 stream eases the capture process.

- Reduces nitrogen oxide emissions.

Challenges:

- Air separation is energy-intensive.

- High operational costs.

Methods of Carbon Storage

Once captured, CO2 must be stored securely. The primary methods of carbon storage include:

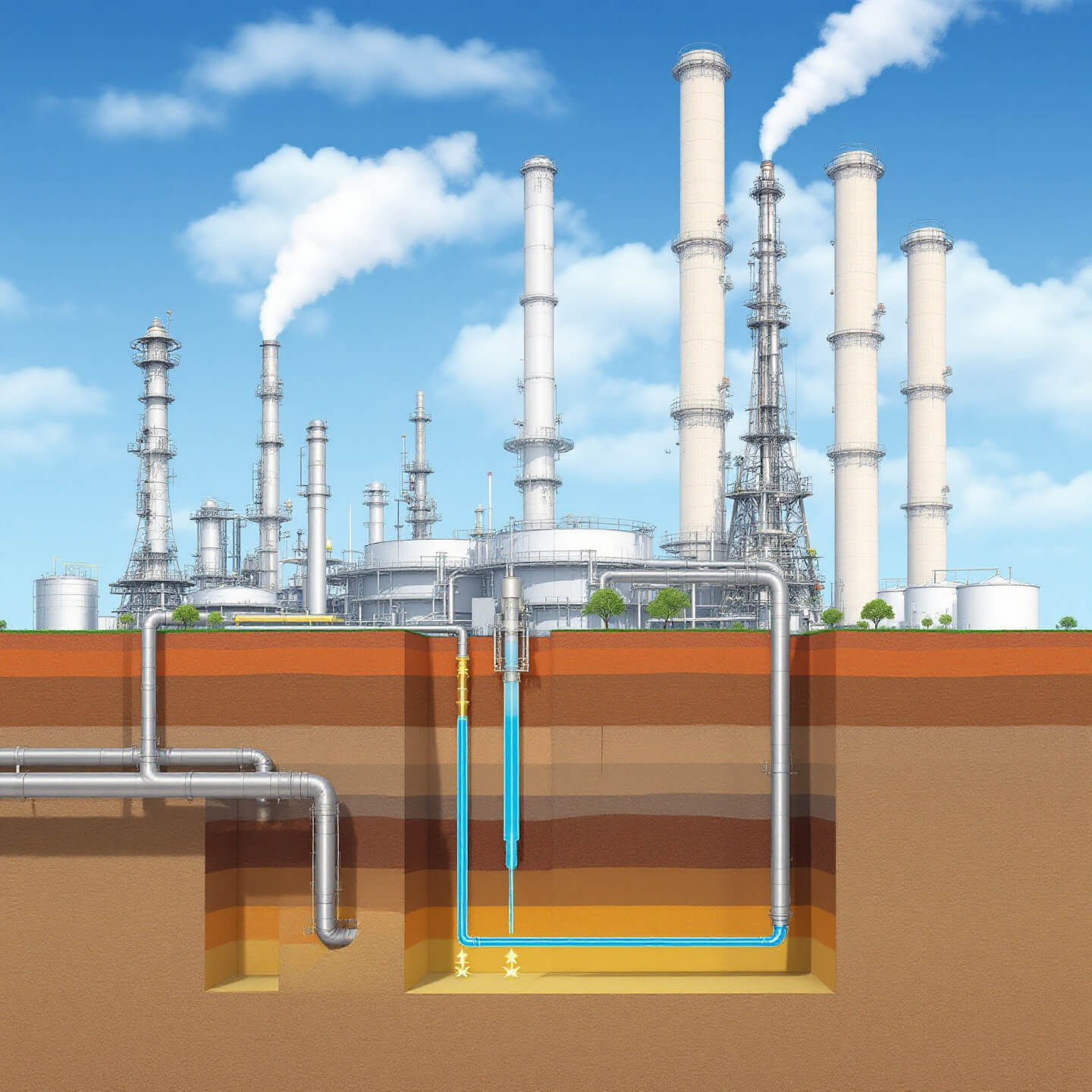

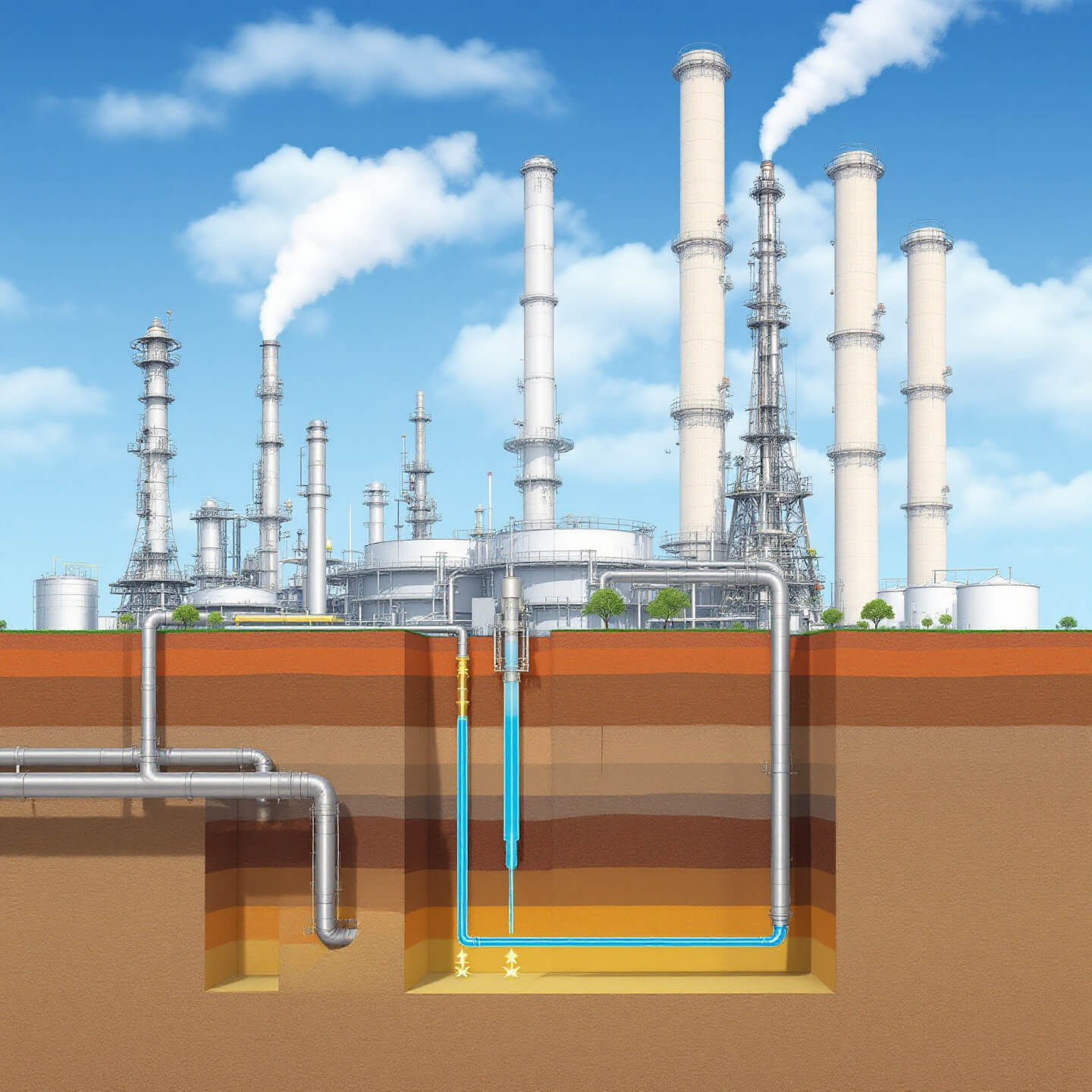

Geological Storage

Geological storage involves injecting CO2 into underground rock formations. Suitable sites include:

- Depleted Oil and Gas Fields: Utilizing existing infrastructure.

- Deep Saline Aquifers: Porous rocks saturated with salty water.

- Unmineable Coal Seams: CO2 replaces methane in coal seams.

Process:

- Site Selection: Geologically stable areas are chosen to prevent leaks.

- Injection: CO2 is compressed and injected deep underground.

- Monitoring: Ongoing surveillance ensures CO2 remains trapped.

Advantages:

- Large storage capacity.

- Proven technology used in enhanced oil recovery.

Challenges:

- Risk of leakage if not properly managed.

- Requires long-term monitoring.

Mineral Carbonation

Mineral carbonation involves reacting CO2 with metal oxides to form stable carbonates.

Process:

- CO2 Reaction: CO2 is reacted with minerals like serpentine or olivine.

- Solid Carbonates Formation: CO2 is permanently fixed in solid form.

Advantages:

- Permanent and stable storage.

- No risk of CO2 leakage.

Challenges:

- Slow natural reaction rates.

- Requires mining of large quantities of minerals.

Utilization of Captured CO2

Instead of storage, captured CO2 can be utilized in various industrial applications:

- Enhanced Oil Recovery (EOR): CO2 is injected into oil reservoirs to increase oil extraction.

- Chemical Production: Used as a feedstock for producing chemicals like urea.

- Biofuel Production: Algae cultivation utilizing CO2 for biofuel.

Advantages:

- Generates additional revenue streams.

- Reduces the net cost of carbon capture.

Challenges:

- Market demand for CO2 utilization is limited compared to emissions volume.

- Potential for re-release of CO2, depending on utilization method.

Challenges and Solutions in CCS Implementation

Technical Challenges:

- Efficiency Loss: Energy required for capture, transport, and storage reduces overall efficiency.

- Infrastructure Needs: Requires extensive pipeline networks and storage facilities.

Economic Challenges:

- High Costs: Significant capital investment and operational costs.

- Market Uncertainty: Fluctuating oil prices impact the economic viability of CCS projects.

Regulatory Challenges:

- Lack of Policies: Insufficient regulatory frameworks to incentivize CCS.

- Liability Issues: Long-term responsibility for stored CO2 is unclear.

Solutions:

- Technological Advancements: Research into more efficient capture materials and methods.

- Government Incentives: Policies like carbon pricing and tax credits.

- Public-Private Partnerships: Collaboration between governments and industry to share risks and costs.

The Future of CCS in the Oil and Gas Industry

The role of CCS is poised to grow as part of a broader strategy to reduce greenhouse gas emissions. Key trends include:

- Integration with Renewable Energy: Combining CCS with bioenergy (BECCS) for negative emissions.

- Digital Technologies: Using AI and data analytics for monitoring and optimizing CCS processes.

- International Collaboration: Global initiatives to share knowledge and resources.

Investments in CCS are accelerating, driven by environmental commitments and the pursuit of sustainable operations. The oil and gas industry is uniquely positioned to leverage its expertise in subsurface technologies for effective CCS implementation.

Conclusion

Carbon Capture and Storage represents a critical pathway for the oil and gas industry to reduce its carbon footprint and contribute to global climate goals. While challenges exist, technological innovations and supportive policies can enable CCS to become a mainstream solution.

By investing in CCS technologies and infrastructure, the industry can not only mitigate environmental impacts but also unlock new economic opportunities. The transition towards cleaner energy is complex, but with CCS, it is a journey that the oil and gas sector can navigate successfully.

For more insights on carbon management and sustainable practices in the oil and gas industry, subscribe to our newsletter and stay updated.

References

- International Energy Agency (IEA) – Carbon Capture, Utilisation and Storage

- Global CCS Institute – The Global Status of CCS

- U.S. Department of Energy – Carbon Storage Research